MAGNETIC MATERIALS

Metglas® Magnetic Materials produced on our proprietary high-speed casting process are used in many specialized applications. Industries have discovered that the unique magnetic properties found in Metglas® Magnetic Materials make them an ideal solution for a wide range of applications from distribution transformers, magnetic anti-theft tags, motors, high frequency inductors and more. Components made from Metglas® help companies worldwide reduce operating costs, strengthen energy conversation efforts and increase application efficiency

METGLAS® 2605SA1 & 2605HB1M Alloy

(Material) iron-based; extremely low core loss

APPLICATIONS:

- Distribution, commercial and industrial transformers

- Motors

- High frequency inductors

- Current transformers

- Devices requiring high permeability and low loss at low frequencies

BENEFITS:

- Extremely low core loss

- 35% of the core loss of grade M3 electrical steel (core loss at 50 Hz is approximately 80% of 60 Hz values). This is for finished cores.

- High permeability

GENERAL PROPERTIES & CHARACTERISTICS |

|

|---|---|

| Electromagnetic | |

| Saturation Induction (T) | – |

| As Cast | 1.56 |

| Maximum DC Permeability (µ) | |

| Annealed | 600,000 |

| As Cast | 45,000 |

| Saturation Magnetostriction (ppm) | 27 |

| Electrical Resistivity (µΩ-cm) | 130 |

| Curie Temperature (°C) | 395 |

| Physical | |

| Thickness (µm) | 23 |

| Standard Available Widths | |

| Minimum (mm) | 5 |

| Maximum (mm) | 213 |

| Density (g/cm3) | 7.18 |

| Vicker’s Hardness (50g Load) | 900 |

| Tensile Strength (GPa) | 1-2 |

| Elastic Modulus (GPa) | 100-110 |

| Lamination Factor (%) | >84 |

| Thermal Expansion (ppm/°C) | 7.6 |

| Crystallization Temperature (°C) | 510 |

| Continuous Service Temp. (°C) | 150 |

- Properties

-

GENERAL PROPERTIES & CHARACTERISTICS

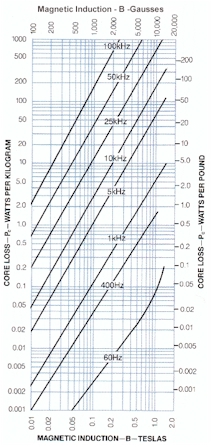

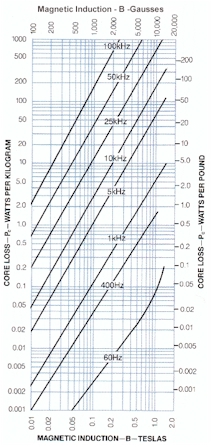

Electromagnetic Saturation Induction (T) – As Cast 1.56 Maximum DC Permeability (µ) Annealed 600,000 As Cast 45,000 Saturation Magnetostriction (ppm) 27 Electrical Resistivity (µΩ-cm) 130 Curie Temperature (°C) 395 Physical Thickness (µm) 23 Standard Available Widths Minimum (mm) 5 Maximum (mm) 213 Density (g/cm3) 7.18 Vicker’s Hardness (50g Load) 900 Tensile Strength (GPa) 1-2 Elastic Modulus (GPa) 100-110 Lamination Factor (%) >84 Thermal Expansion (ppm/°C) 7.6 Crystallization Temperature (°C) 510 Continuous Service Temp. (°C) 150 - Graph 1

-

- Graph 2

-

- Graph 3

-

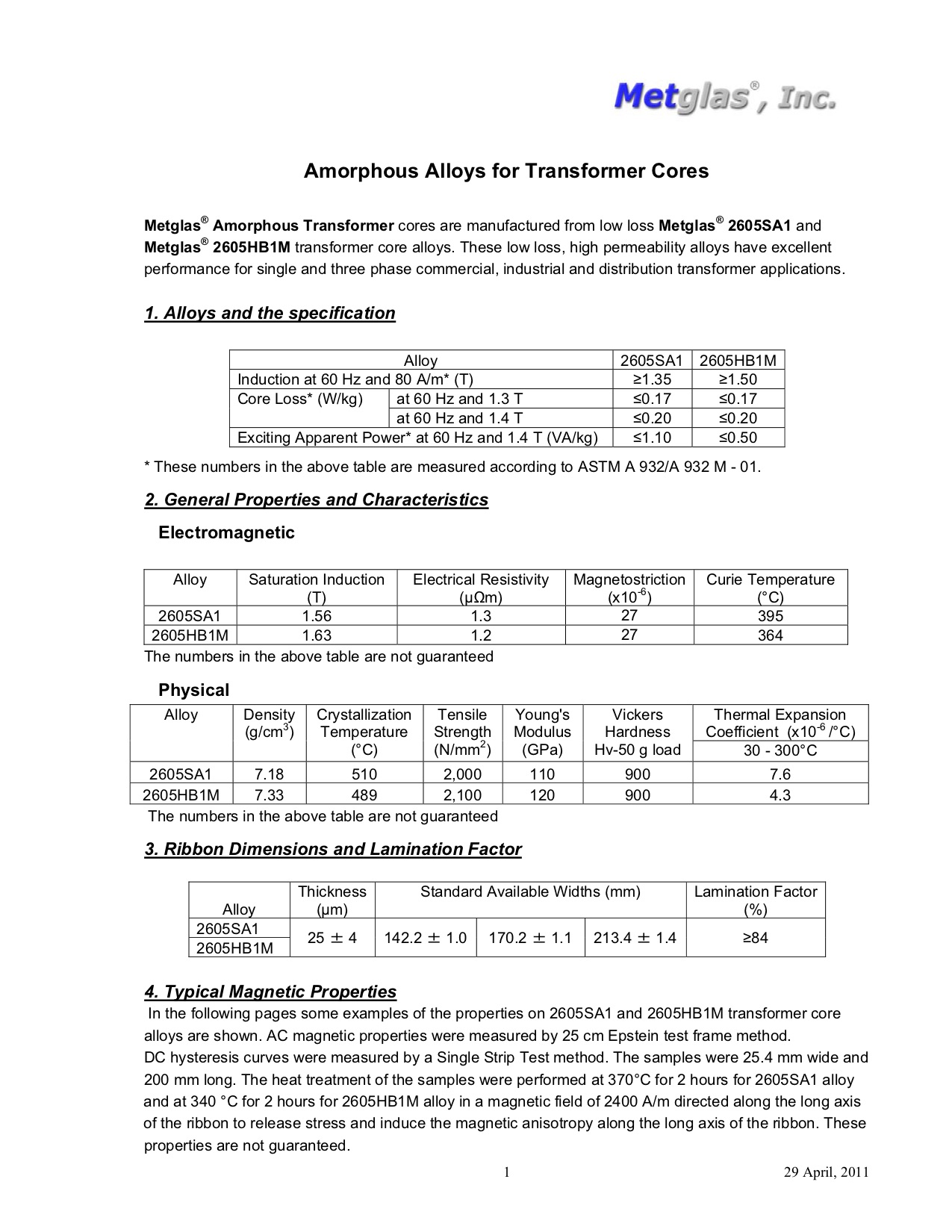

- Brochure 1

- Brochure 2

METGLAS® 2605S3A Alloy

(Material) iron-based; high permeability

APPLICATIONS:

- Current transformers

- Ground fault protection devices

- High frequency cores

BENEFITS:

- Low core loss at high frequencies (>1 kHz)

- High operating temperature with minimal flux density reduction

- Can be annealed for high permeability in low or high frequencies

| General Properties & Characteristics | |

|---|---|

| Electromagnetic | |

| Saturation Induction (T) | 1.41 |

| Maximum DC Permeability (µ) | |

| Annealed | 35,000 |

| As Cast | >20,000 |

| Saturation Magnetostriction (ppm) | 20 |

| Electrical Resistivity (µΩ-cm) | 138 |

| Curie Temperature (°C) | 358 |

| Physical | |

| Thickness (microns) | 18 |

| Standard Available Widths | |

| Minimum (mm) | 2.5 |

| Maximum (mm) | 50 |

| Density (g/cm3) | 7.29 |

| Vicker’s Hardness (50g Load) | 860 |

| Tensile Strength (GPa) | 1-2 |

| Elastic Modulus (GPa) | 100-110 |

| Lamination Factor (%) | >75 |

| Thermal Expansion (ppm/°C) | 6.7 |

| Crystallization Temperature (°C) | 535 |

| Continuous Service Temp. (°C) | 150 |

- Properties

-

General Properties & Characteristics Electromagnetic Saturation Induction (T) 1.41 Maximum DC Permeability (µ) Annealed 35,000 As Cast >20,000 Saturation Magnetostriction (ppm) 20 Electrical Resistivity (µΩ-cm) 138 Curie Temperature (°C) 358 Physical Thickness (microns) 18 Standard Available Widths Minimum (mm) 2.5 Maximum (mm) 50 Density (g/cm3) 7.29 Vicker’s Hardness (50g Load) 860 Tensile Strength (GPa) 1-2 Elastic Modulus (GPa) 100-110 Lamination Factor (%) >75 Thermal Expansion (ppm/°C) 6.7 Crystallization Temperature (°C) 535 Continuous Service Temp. (°C) 150 - Graph 1

-

- Graph 2

-

- Graph 3

-

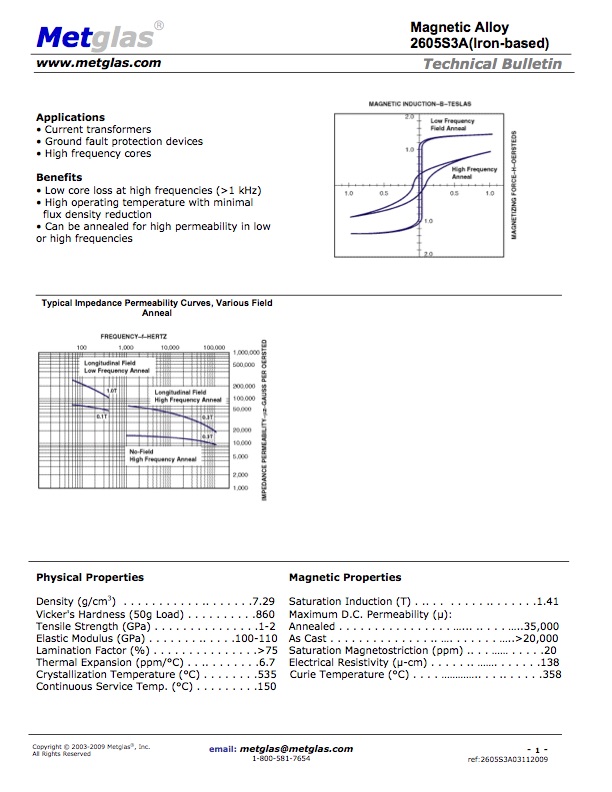

- Brochure 1

- Brochure 2

METGLAS® 2705M Alloy

(Material) cobalt-based; near-zero magnetostriction

APPLICATIONS:

- Flexible electromagnetic shielding

- Magnetic sensors

- High frequency cores

- Magnetic Switches

BENEFITS:

- Near-zero magnetostriction

- High permeability and square BH loop without annealing

- Can be annealed for square or linear permeability

- Medium saturation induction

| General Properties & Characteristics | |

|---|---|

| ELECTROMAGNETIC | |

| Saturation Induction (T) | 0.77 |

| Maximum DC Permeability (µ) | |

| As Cast | 290,000 |

| Saturation Magnetostriction (ppm) | <0.5 |

| Electrical Resistivity (µΩ-cm) | 136 |

| Curie Temperature (°C) | 365 |

| PHYSICAL | |

| Thickness (microns) | 22 |

| Standard Available Widths | |

| Minimum (mm) | 2.5 |

| Maximum (mm) | 50 |

| Density (g/cm3) | – |

| As Cast | 7.8 |

| Vicker’s Hardness (50g Load) | 880 |

| Tensile Strength (GPa) | 1-2 |

| Elastic Modulus (GPa) | 100-110 |

| Lamination Factor (%) | >75 |

| Thermal Expansion (ppm/°C) | 12 |

| Crystallization Temperature (°C) | 520 |

| Continuous Service Temp. (°C) | 90 |

- Properties

-

General Properties & Characteristics ELECTROMAGNETIC Saturation Induction (T) 0.77 Maximum DC Permeability (µ) As Cast 290,000 Saturation Magnetostriction (ppm) <0.5 Electrical Resistivity (µΩ-cm) 136 Curie Temperature (°C) 365 PHYSICAL Thickness (microns) 22 Standard Available Widths Minimum (mm) 2.5 Maximum (mm) 50 Density (g/cm3) – As Cast 7.8 Vicker’s Hardness (50g Load) 880 Tensile Strength (GPa) 1-2 Elastic Modulus (GPa) 100-110 Lamination Factor (%) >75 Thermal Expansion (ppm/°C) 12 Crystallization Temperature (°C) 520 Continuous Service Temp. (°C) 90 - Graph 1

-

- Graph 2

-

- Graph 3

-

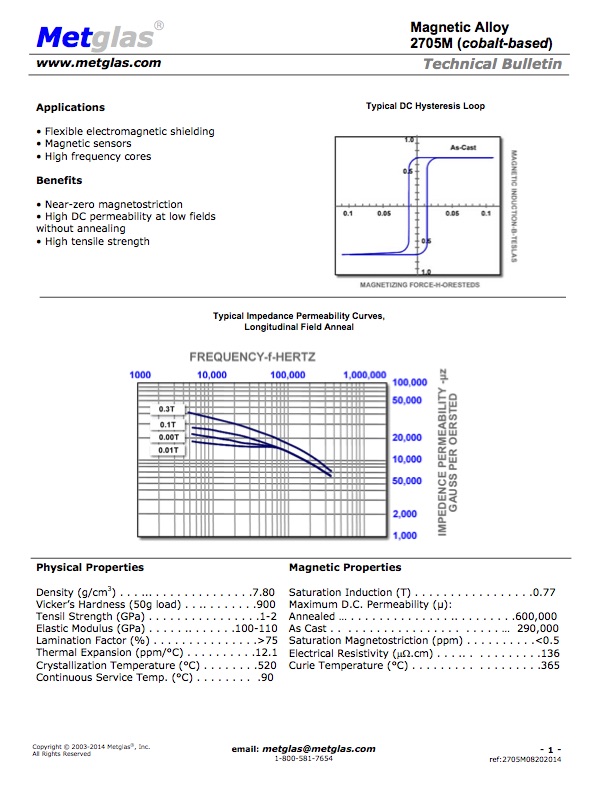

- Brochure 1

- Brochure 2

METGLAS® 2714A Alloy

(Material) cobalt-based; near-zero magnetostriction

APPLICATIONS:

- Switch-mode power supply applications

- Magnetic amplifiers

- Semiconductor noise suppression cores

- High frequency transformers

- High sensitivity matching transformers

- Ultra-sensitive current transformers

- Shielding

- Sensor applications

BENEFITS:

- Extremely low core loss

- Ultrahigh permeability

- High squareness ratio – low coercive force

- Near-zero magnetostriction

- Excellent corrosion resistance

- Can be annealed for linear BH loop

| GENERAL PROPERTIES & CHARACTERISTICS | |

|---|---|

| Electromagnetic | |

| Saturation Induction (T) | 0.57 |

| Maximum DC Permeability (µ) | |

| Annealed | 1,000,000 |

| As Cast | >80,000 |

| Saturation Magnetostriction (ppm) | <0.5 |

| Electrical Resistivity (µΩ-cm) | 142 |

| Curie Temperature (°C) | 225 |

| Physical | |

| Thickness (microns) | 15 |

| Standard Available Widths | |

| Minimum (mm) | 2.5 |

| Maximum (mm) | 50 |

| Density (g/cm3) | 7.59 |

| Vicker’s Hardness (50g Load) | 960 |

| Tensile Strength (GPa) | 1-2 |

| Elastic Modulus (GPa) | 100-110 |

| Lamination Factor (%) | >75 |

| Thermal Expansion (ppm/°C) | 12.7 |

| Crystallization Temperature (°C) | 550 |

| Continuous Service Temp. (°C) | 90 |

- Properties

-

GENERAL PROPERTIES & CHARACTERISTICS Electromagnetic Saturation Induction (T) 0.57 Maximum DC Permeability (µ) Annealed 1,000,000 As Cast >80,000 Saturation Magnetostriction (ppm) <0.5 Electrical Resistivity (µΩ-cm) 142 Curie Temperature (°C) 225 Physical Thickness (microns) 15 Standard Available Widths Minimum (mm) 2.5 Maximum (mm) 50 Density (g/cm3) 7.59 Vicker’s Hardness (50g Load) 960 Tensile Strength (GPa) 1-2 Elastic Modulus (GPa) 100-110 Lamination Factor (%) >75 Thermal Expansion (ppm/°C) 12.7 Crystallization Temperature (°C) 550 Continuous Service Temp. (°C) 90 - Graph 1

-

- Graph 2

-

- Graph 3

-

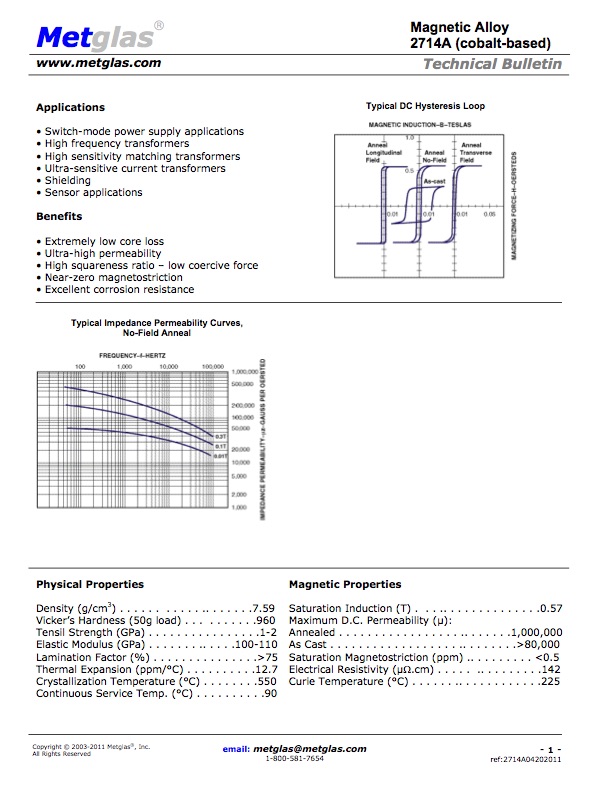

- Brochure 1

- Brochure 2

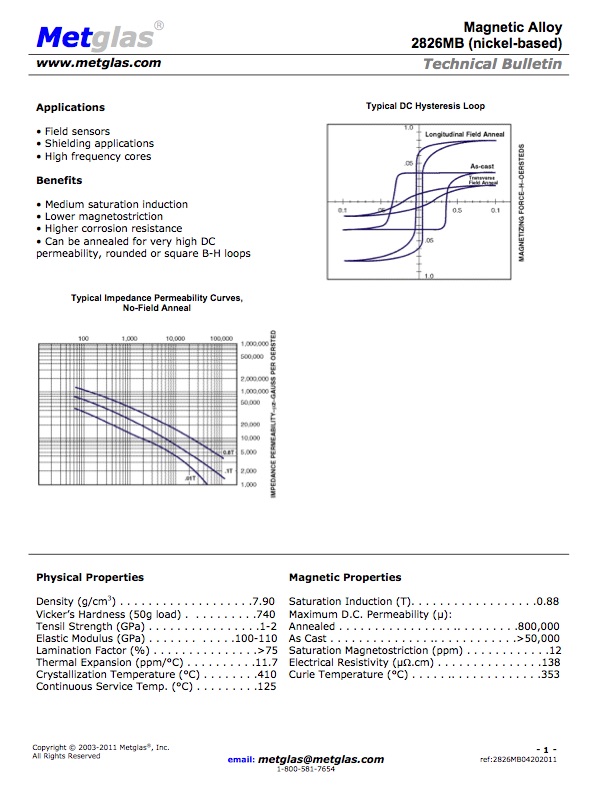

METGLAS® 2826MB Alloy

(Material) iron nickel-based: medium saturation

APPLICATIONS:

- Field sensors

- Shielding applications

- High frequency cores

- Magnetomechanical sensors

BENEFITS:

- Medium saturation induction

- Lower magnetostriction

- Higher corrosion resistance

- Can be annealed for high permeability, rounded or square BH loop

| GENERAL PROPERTIES & CHARACTERISTICS | |

|---|---|

| Electromagnetic | |

| Saturation Induction (T) | 0.88 |

| Maximum DC Permeability (µ) | |

| Annealed | 800,000 |

| As Cast | >50,000 |

| Saturation Magnetostriction (ppm) | 12 |

| Electrical Resistivity (µΩ-cm) | 138 |

| Curie Temperature (°C) | 353 |

| Physical | |

| Thickness (microns) | 29 |

| Standard Available Widths | |

| Minimum (mm) | 2.5 |

| Maximum (mm) | 12.7 |

| Density (g/cm3) | 7.9 |

| Vicker’s Hardness (50g Load) | 740 |

| Tensile Strength (GPa) | 1-2 |

| Elastic Modulus (GPa) | 100-110 |

| Lamination Factor (%) | >75 |

| Thermal Expansion (ppm/°C) | 11.7 |

| Crystallization Temperature (°C) | 410 |

| Continuous Service Temp. (°C) | 125 |

- Properties

-

GENERAL PROPERTIES & CHARACTERISTICS Electromagnetic Saturation Induction (T) 0.88 Maximum DC Permeability (µ) Annealed 800,000 As Cast >50,000 Saturation Magnetostriction (ppm) 12 Electrical Resistivity (µΩ-cm) 138 Curie Temperature (°C) 353 Physical Thickness (microns) 29 Standard Available Widths Minimum (mm) 2.5 Maximum (mm) 12.7 Density (g/cm3) 7.9 Vicker’s Hardness (50g Load) 740 Tensile Strength (GPa) 1-2 Elastic Modulus (GPa) 100-110 Lamination Factor (%) >75 Thermal Expansion (ppm/°C) 11.7 Crystallization Temperature (°C) 410 Continuous Service Temp. (°C) 125 - Graph 1

-

- Graph 2

-

- Graph 3

-

- Brochure 1

- Brochure 2