Metglas® Inc., located in Conway, SC, is a world leading producer of Amorphous Metal Ribbon. Since our company began in the 1970’s, Metglas, Inc. (then Allied Signal located in Morristown, NJ) pioneered the development and production of amorphous metal, a unique alloy that exhibits a structure in which the metal atoms occur in a random pattern. The key to Metglas Inc.’s proprietary manufacturing process is the rapid-solidification of molten alloy at a rate of approximately one million degrees Celsius per second.

Metglas Amorphous Metals have a unique non-crystalline structure and possess excellent physical and magnetic properties that combine strength and hardness with flexibility and toughness. Metglas and Metglas products can help companies around the globe reduce their operating costs, strengthen energy conservation efforts and increase application efficiency.

KEY PRODUCTS

- Metglas®

- Amorphous Metals

- Glassy Metals

- Transformer Core Alloys

- Metglas Brazing Filler Metal

- Distribution Transformer Core Ribbon

- Industrial Transformer Core Ribbon

- Pulse Power Cores

APPLICATIONS

- Electrical Distribution Transformers

- Industrial Power Distribution Transformers

- High Frequency Magnetic Components for Power Electronics

- Material for Anti -Theft tags

- High Efficiency Inverters and Inductorsrrs

- Solar and Wind Inverters

- Harmonic Filters

- Pulse Power Cores for Lasers

- High Power Magnetic Forms for Medical Use

- High Purity Brazing Filler Metals

- Motors (Amorphous Stators)

METGLAS®, Inc. will lead the World in Amorphous and Rapidly Quenched Metal Casting Technology and Production

METGLAS®, Inc. is committed to satisfying all applicable requirements and will strive to exceed Customer Expectations using the creative input of our employees to continually improve our products and processes.

METGLAS®, Inc. will lead the World in Amorphous and Rapidly Quenched Metal Casting Technology and Production

METGLAS®, Inc. is committed to satisfying all applicable requirements and will strive to exceed Customer Expectations using the creative input of our employees to continually improve our products and processes.

METGLAS COMPANY HISTORY

1970s Product Development – Corporate R&D

- 1973 – Discovery of Metglas® Amorphous Alloy Announced (AlliedSignal)

- 1978 – Transformer Core Alloy Developed & Introduced

- 1979 – Pilot Continuous Casting Line – AlliedSignal Headquarters, Morristown, NJ (USA)

1980s Process Development – Strategic Business Unit

- 1982 – Installed First Commercial Transformers in USA

- Mid 1980’s – Development of Ni-based Brazing Alloys primarily for Aerospace market

- 1989 – Commenced Production of Transformer Core Alloy – Conway, SC (USA)

1990s Commercial Operation for Metglas Alloys

- Mid 1990’s – 6-8% of distribution transformers bought in USA utilized Metglas

- Mid 1990’s – Development of Ni-based Brazing Alloys for the Heat Exchanger/Automotive market

- 1999 – AlliedSignal buys Honeywell – takes Honeywell name

2000s Commercial Development / Increase of Capacity

- 2000 – Initial Automotive designs become commercialized using Metglas Brazing Foils

- 2003 – Purchase of Metglas by Hitachi Metals Ltd (Japan) from Honeywell

- 2010 – Hitachi Metals increases global capacity to 100kMT/yr (including upgrade to Brazing Lines)

- 2015 – Commercial Development/Launch of wide Nano-Crystalline product in Conway, SC

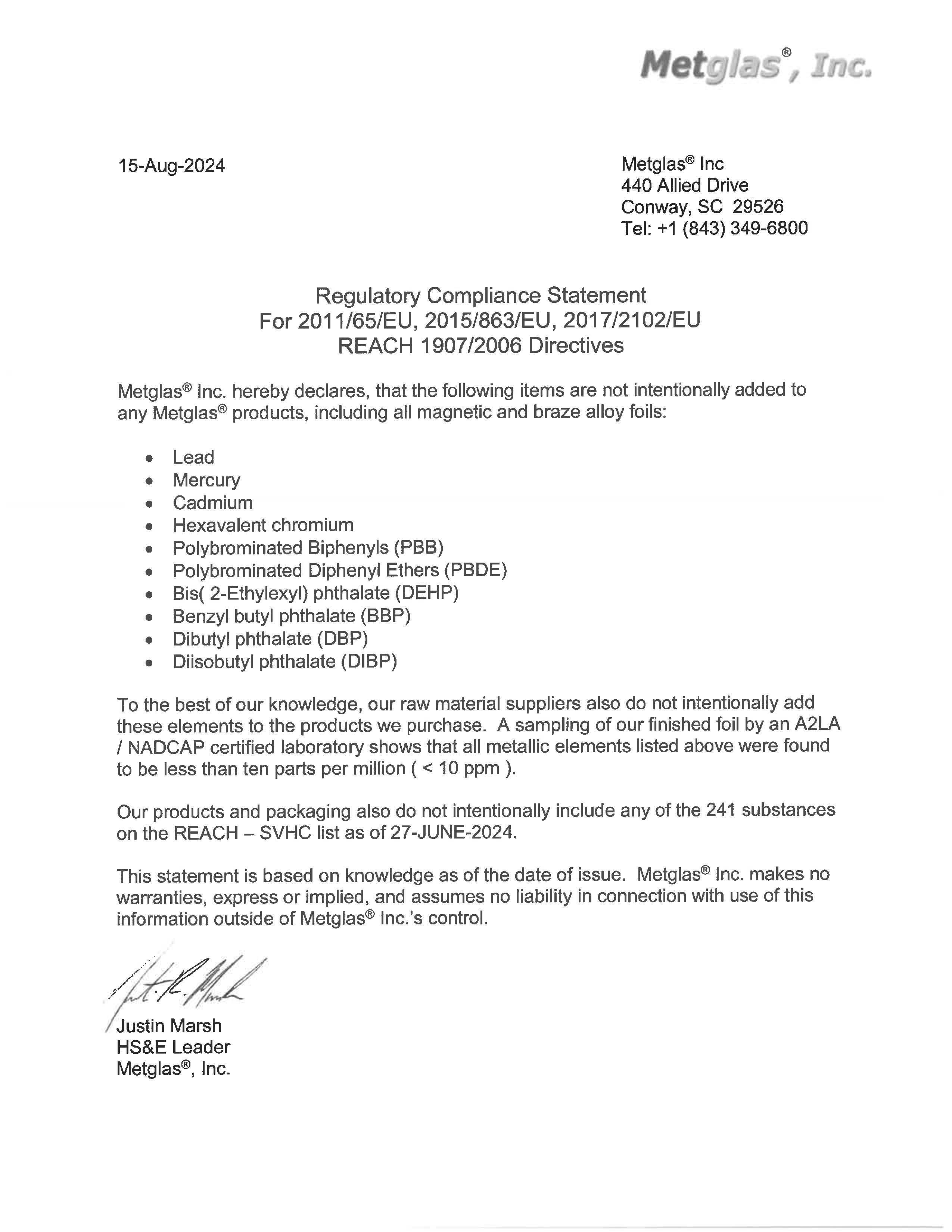

ROHS COMPLIANCE

Metglas® Inc. hereby declares, that the following items are not intentionally added to any Metglas® products, including all magnetic and braze alloy foils:

- Lead

- Mercury

- Cadmium

- Hexavalent chromium

- Polybrominated Biphenyls (PBB)

- Polybrominated Diphenyl Ethers (PBDE)

- Bis( 2-Ethylexyl) phthalate (DEHP)

- Benzyl butyl phthalate (BBP)

- Dibutyl phthalate (DBP)

- Diisobutyl phthalate (DIBP)

To the best of our knowledge, our raw material suppliers also do not intentionally add these elements to the products we purchase. A sampling of our finished foil by an A2LA / NADCAP certified laboratory shows that all metallic elements listed above were found to be less than ten parts per million ( < 10 ppm ). Our products and packaging also do not intentionally include any of the 223 substances on the REACH – SVHC list as of Rev. 24 (17/Jan/2022).

This statement is based on knowledge as of the date of issue. Metglas® Inc. makes no warranties, express or implied, and assumes no liability in connection with the use of this information outside of Metglas® Inc.’s control.