Reducing costs and improving savings

More than ever, electric utilities and industries today are searching for technologies that will reduce their operating costs and improve energy savings throughout their systems. New transmission and distribution (T&D) technologies are now available to help utilities meet these goals.

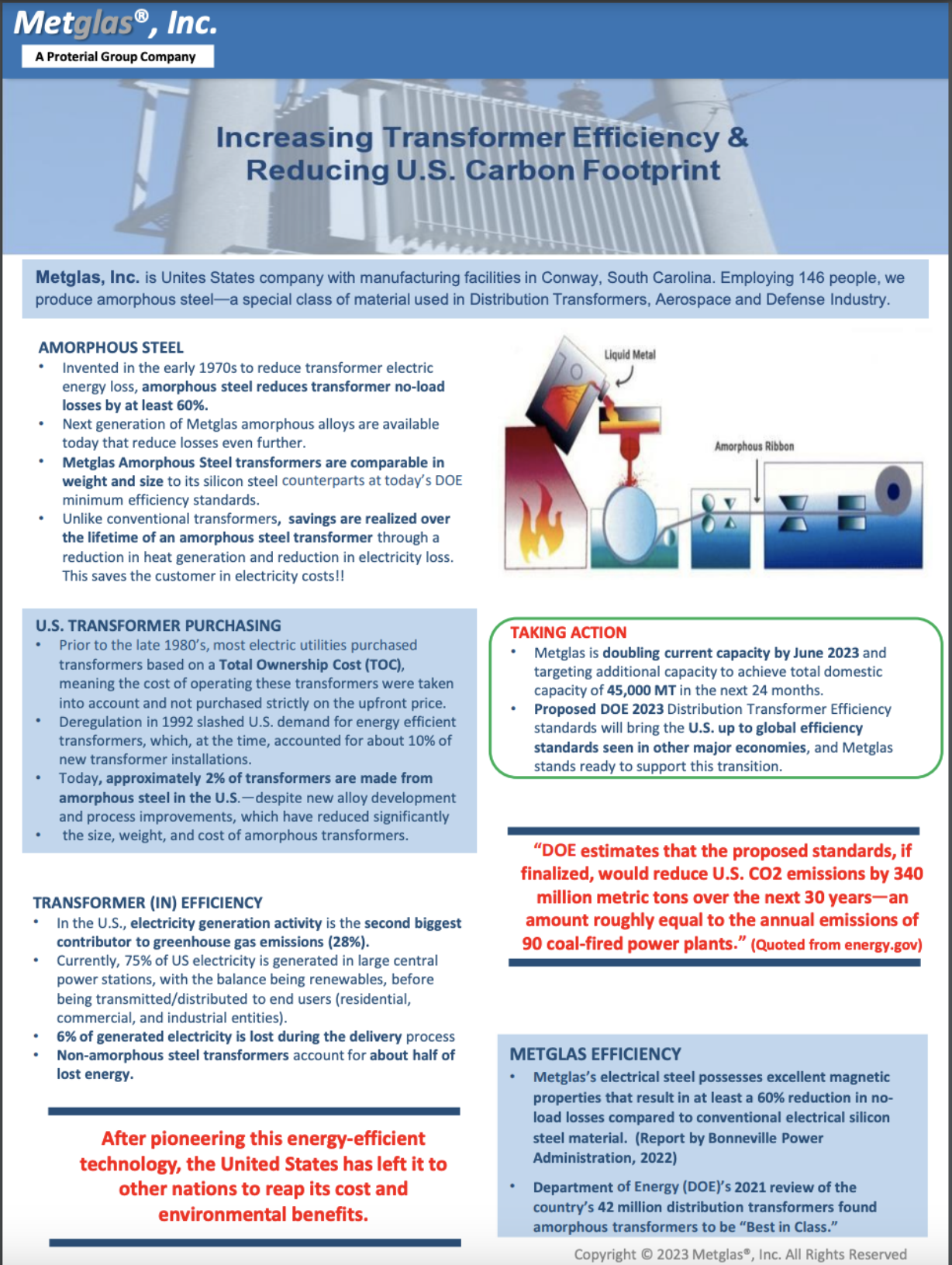

With Metglas® amorphous metal distribution transformers (AMDTs) — with up to 70% lower core loss than conventional transformers — Metglas, Inc. is helping utilities worldwide to achieve their efficiency objectives. When you consider that 10% of all electricity generated by utilities is lost in the transmission & distribution process, the potential savings through reductions in core loss can be significant.

Ultra-efficient transformer cores made with Metglas® amorphous metal alloy make lower core losses possible. Amorphous metal distribution transformers are key to improving utility economics and enhancing energy conservation efforts worldwide.

Increasing Transformer Efficiency and Reducing U.S. Carbon Footprint

Metglas Amorphous Metal Transformer Core

Benefits

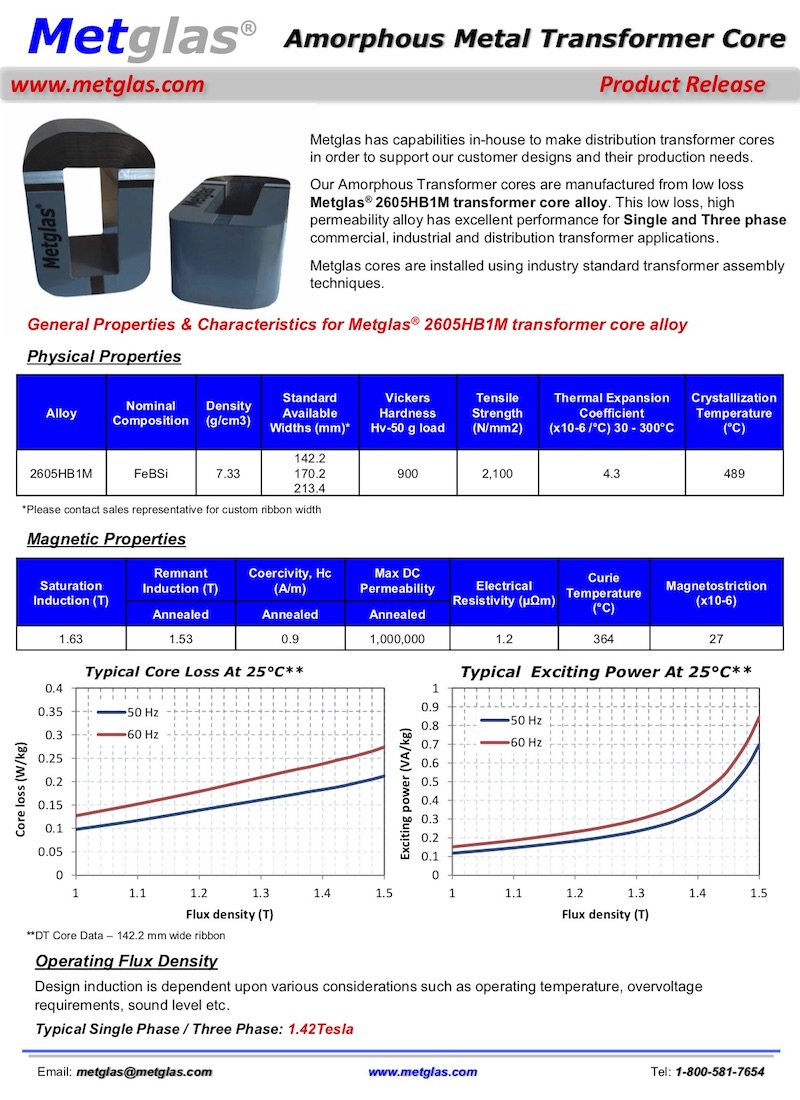

Our Amorphous Transformer cores are manufactured from low loss Metglas®2605HB1M transformer core alloy. This low loss, high permeability alloy has excellent performance for Single and Three phase commercial, industrial and distribution transformer applications.

Metglas cores are installed using industry standard transformer assembly techniques.

Physical Properties

| Alloy | Nominal composition | Density (g.cm3) | Standard available widths (mm)* | Vickers hardness Hv-50 g load | Tensile Strength (n/mm2) | Thermal expansion coefficient (x10-6 /0°C) 30 – 300°C | Crystallization Temperature (°C) |

| 2605HB1M | FeBSi | 7.33 | 142.2, 170.2, 213.4 | 900 | 2,100 | 4.3 | 489 |

*Please contact sales representative for custom ribbon width

Magnetic Properties

| Saturation Induction (T) | Remnant Induction (T) Annealed | Coercivity, Hc (A/m) Annealed | Max PC Permeability | Electrical Resistivity (μΩm) |

Curie Temperature (°C) |

Magnetostriction (x10-6) |

| 1.63 | 1.53 | 0.9 | 1,000,000 | 1.2 | 364 | 27 |

- Brochure 1

- Table Properties

-

Physical Properties

Alloy Nominal composition Density (g.cm3) Standard available widths (mm)* Vickers hardness Hv-50 g load Tensile Strength (n/mm2) Thermal expansion coefficient (x10-6 /0°C) 30 – 300°C Crystallization Temperature (°C) 2605HB1M FeBSi 7.33 142.2, 170.2, 213.4 900 2,100 4.3 489 *Please contact sales representative for custom ribbon width

Magnetic Properties

Saturation Induction (T) Remnant Induction (T) Annealed Coercivity, Hc (A/m) Annealed Max PC Permeability Electrical Resistivity (μΩm) Curie Temperature (°C)

Magnetostriction (x10-6)

1.63 1.53 0.9 1,000,000 1.2 364 27

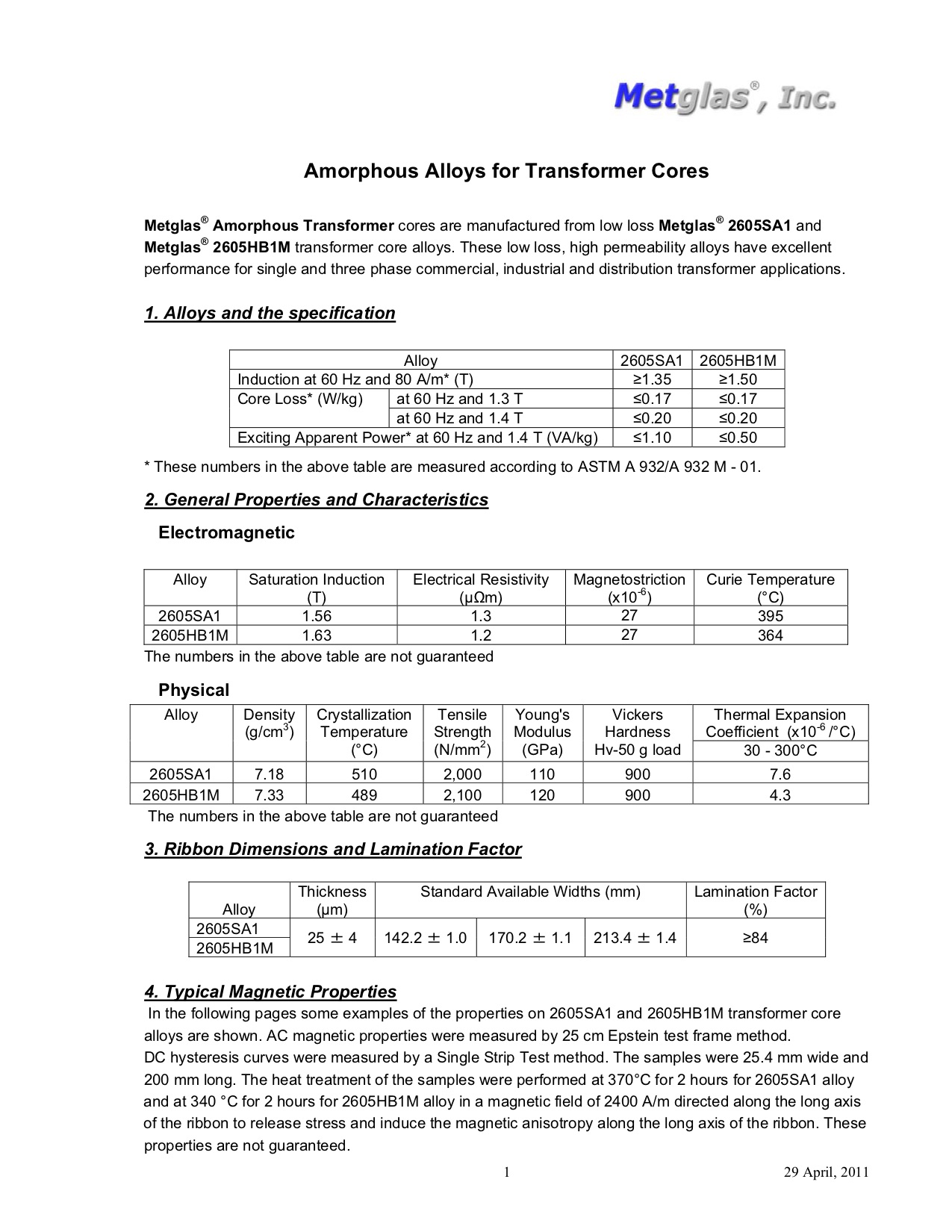

METGLAS® 2605HB1M & 2605SA1 Alloy

(Material) iron-based; extremely low core loss

APPLICATIONS:

- Distribution, commercial and industrial transformers

- Motors

- High frequency inductors

- Current transformers

- Devices requiring high permeability and low loss at low frequencies

BENEFITS:

- Extremely low core loss

- 35% of the core loss of grade M3 electrical steel (core loss at 50 Hz is approximately 70% of 60 Hz values). This is for finished cores.

- High permeability

LIFETIME AMORPHOUS BENEFITS

TOTAL OWNING COST BASIS

Amorphous Metal Transformer Purchases on a Total Owning Cost Basis

One method of illustrating how Amorphous Metal Distribution Transformers (AMDTs) provide economic savings is by evaluating on a Total Owning Cost (TOC) basis. TOC encompasses both the initial cost of the transformer, plus the future cost of the energy losses over the life of the equipment.

One method of illustrating how Amorphous Metal Distribution Transformers (AMDTs) provide economic savings is by evaluating on a Total Owning Cost (TOC) basis. TOC encompasses both the initial cost of the transformer, plus the future cost of the energy losses over the life of the equipment.

The essence of transformer loss evaluation is to recognize that there is a cost of losses associated with the distribution transformer purchase decision that is just as important as the initial price. A user who saves on the initial purchase price of the transformer may in fact be losing money by not properly considering the value of the energy losses over the transformer’s active life.

TOC = Initial Purchase Price + Cost of Future Energy Losses.

This chart illustrates that despite a higher initial cost, the use of AMDTs results in overall financial savings for utilities over the life of the transformer, compared with the use of conventional silicon steel core transformers.

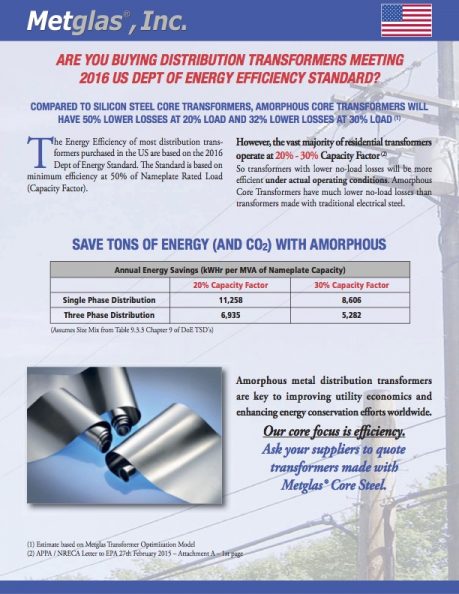

DEPARTMENT OF ENERGY 2016

Compared to silicon steel core transformers, amorphous core transformers will have 50% lower losses at 20% load and 32% lower losses at 30% load (1)

The energy efficiency of most distribution transformers purchased in the US are based on the 2016 Dept of Energy Standard. The Standard is based on minimum efficiency at 50% of Nameplate Rated Load (Capacity Factor).

However, the vast majority of residential transformers operate at 20% – 30% Capacity Factor (2)

So transformers with lower no-load losses will be more efficient under actual operating conditions. Amorphous Core Transformers have much lower no-load losses than transformers made with traditional electrical steel.

(2) APPA / NRECA Letter to EPA 27th February 2015 – Attachment A – 1st page

SAVE TONS OF ENERGY (AND CO2) WITH AMORPHOUS

|

Annual Energy Savings (kWHr per MVA of Nameplate Capacity) |

||

| Transformer |

20% Capacity Factor |

30% Capacity Factor |

|

Single Phase Distribution |

11,258 |

8,606 |

|

Three Phase Distribution |

6,935 |

5,282 |

(Assumes Size Mix from Table 9.3.3 Chapter 9 of DoE TSD’s)

Amorphous metal distribution transformers are key to improving utility economics and enhancing energy conservation efforts worldwide.

Our core focus is efficiency.

Ask your suppliers to quote transformers made with Metglas® Core Steel.

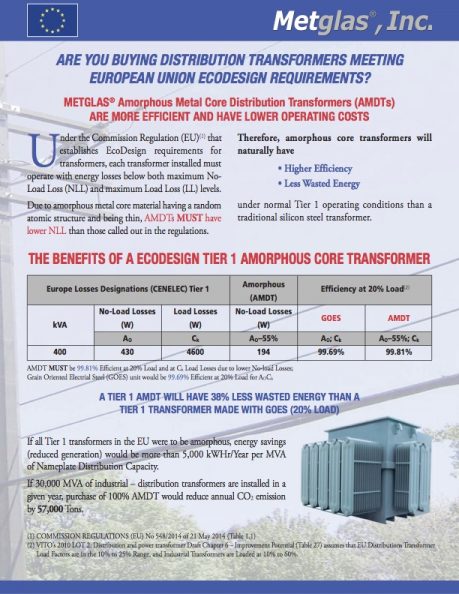

EUROPEAN UNION ECODESIGN

METGLAS® Amorphous Metal Core Distribution Transformers (AMDTs) are more efficient and have lower operating costs

Under the Commission Regulation (EU) (1) that establishes EcoDesign requirements for transformers, each transformer installed must operate with energy losses below both maximum No- Load Loss (NLL) and maximum Load Loss (LL) levels.

Due to amorphous metal core material having a random atomic structure and being thin, AMDTs MUST have lower NLL than those called out in the regulations.

Therefore, amorphous core transformers will naturally have higher efficiency and less wasted energy under normal Tier 1 operating conditions than a traditional silicon steel transformer.

THE BENEFITS OF A ECODESIGN TIER 1 AMORPHOUS CORE TRANSFORMER

|

Europe Losses Designations

(CENELEC) Tier 1

|

Amorphous

(AMDT)

|

Efficiency at

20% Load (2)

|

|||

|

kVA

|

No-Load Losses (W)

|

Load Losses (W)

|

No-Load Losses (W)

|

GOES

|

AMDT

|

|

Ao

|

Ck

|

Ao–55%

|

Ao; Ck

|

Ao–55%; Ck

|

|

|

400

|

430

|

4600

|

194

|

99.69%

|

99.81%

|

(1) COMMISSION REGULATIONS (EU) No 548/2014 of 21 May 2014 (Table 1.1)

(2) VITO’s 2010 LOT 2: Distribution and power transformer Draft Chapter 6 – Improvement Potential (Table 27) assumes that EU Distributions Transformer Load Factors are in the 10% to 25% Range, and Industrial Transformers are Loaded at 10% to 60

AMDT MUST be 99.81% E cient at 20% Load and at Ck Load Losses due to lower No-load Losses; Grain Oriented Electrial Steel (GOES) unit would be 99.69% Efficient at 20% Load for AoCk

A Tier 1 AMDT will have 38% less wasted energy than a Tier 1 transformer made with GOES (20% load)

If all Tier 1 transformers in the EU were to be amorphous, energy savings (reduced generation) would be more than 5,000 kWHr/Year per MVA of Nameplate Distribution Capacity.

If 30,000 MVA of industrial – distribution transformers are installed in a given year, purchase of 100% AMDT would reduce annual CO2 emission by 57,000 Tons.

- ToC

-

TOTAL OWNING COST BASIS

Amorphous Metal Transformer Purchases on a Total Owning Cost Basis

One method of illustrating how Amorphous Metal Distribution Transformers (AMDTs) provide economic savings is by evaluating on a Total Owning Cost (TOC) basis. TOC encompasses both the initial cost of the transformer, plus the future cost of the energy losses over the life of the equipment.

One method of illustrating how Amorphous Metal Distribution Transformers (AMDTs) provide economic savings is by evaluating on a Total Owning Cost (TOC) basis. TOC encompasses both the initial cost of the transformer, plus the future cost of the energy losses over the life of the equipment.The essence of transformer loss evaluation is to recognize that there is a cost of losses associated with the distribution transformer purchase decision that is just as important as the initial price. A user who saves on the initial purchase price of the transformer may in fact be losing money by not properly considering the value of the energy losses over the transformer’s active life.

TOC = Initial Purchase Price + Cost of Future Energy Losses.

This chart illustrates that despite a higher initial cost, the use of AMDTs results in overall financial savings for utilities over the life of the transformer, compared with the use of conventional silicon steel core transformers. - DoE 2016

-

DEPARTMENT OF ENERGY 2016

Compared to silicon steel core transformers, amorphous core transformers will have 50% lower losses at 20% load and 32% lower losses at 30% load (1)

The energy efficiency of most distribution transformers purchased in the US are based on the 2016 Dept of Energy Standard. The Standard is based on minimum efficiency at 50% of Nameplate Rated Load (Capacity Factor).

However, the vast majority of residential transformers operate at 20% – 30% Capacity Factor (2)

So transformers with lower no-load losses will be more efficient under actual operating conditions. Amorphous Core Transformers have much lower no-load losses than transformers made with traditional electrical steel.(1) Estimate based on Metglas Transformer Optimization Model

(2) APPA / NRECA Letter to EPA 27th February 2015 – Attachment A – 1st pageSAVE TONS OF ENERGY (AND CO2) WITH AMORPHOUS

Annual Energy Savings (kWHr per MVA of Nameplate Capacity)

Transformer 20% Capacity Factor

30% Capacity Factor

Single Phase Distribution

11,258

8,606

Three Phase Distribution

6,935

5,282

(Assumes Size Mix from Table 9.3.3 Chapter 9 of DoE TSD’s)

Amorphous metal distribution transformers are key to improving utility economics and enhancing energy conservation efforts worldwide.

Our core focus is efficiency.

Ask your suppliers to quote transformers made with Metglas® Core Steel.

- Tier 1 for The EU

-

EUROPEAN UNION ECODESIGN

METGLAS® Amorphous Metal Core Distribution Transformers (AMDTs) are more efficient and have lower operating costs

Under the Commission Regulation (EU) (1) that establishes EcoDesign requirements for transformers, each transformer installed must operate with energy losses below both maximum No- Load Loss (NLL) and maximum Load Loss (LL) levels.

Due to amorphous metal core material having a random atomic structure and being thin, AMDTs MUST have lower NLL than those called out in the regulations.

Therefore, amorphous core transformers will naturally have higher efficiency and less wasted energy under normal Tier 1 operating conditions than a traditional silicon steel transformer.

THE BENEFITS OF A ECODESIGN TIER 1 AMORPHOUS CORE TRANSFORMER

Europe Losses Designations(CENELEC) Tier 1Amorphous(AMDT)Efficiency at20% Load (2)kVANo-Load Losses (W)Load Losses (W)No-Load Losses (W)GOESAMDTAoCkAo–55%Ao; CkAo–55%; Ck400430460019499.69%99.81%(1) COMMISSION REGULATIONS (EU) No 548/2014 of 21 May 2014 (Table 1.1)

(2) VITO’s 2010 LOT 2: Distribution and power transformer Draft Chapter 6 – Improvement Potential (Table 27) assumes that EU Distributions Transformer Load Factors are in the 10% to 25% Range, and Industrial Transformers are Loaded at 10% to 60AMDT MUST be 99.81% E cient at 20% Load and at Ck Load Losses due to lower No-load Losses; Grain Oriented Electrial Steel (GOES) unit would be 99.69% Efficient at 20% Load for AoCk

A Tier 1 AMDT will have 38% less wasted energy than a Tier 1 transformer made with GOES (20% load)

If all Tier 1 transformers in the EU were to be amorphous, energy savings (reduced generation) would be more than 5,000 kWHr/Year per MVA of Nameplate Distribution Capacity.

If 30,000 MVA of industrial – distribution transformers are installed in a given year, purchase of 100% AMDT would reduce annual CO2 emission by 57,000 Tons.

BENEFITS OF USING AMORPHOUS METAL DISTRIBUTION (AMDT)

Running Cool for Lower Energy Costs

Today, hundreds of utilities are benefiting from the use of Amorphous Metal Distribution Transformers (AMDT’s) in their power distribution systems. Many more utilities can benefit from a strategic program of replacing conventional distribution transformers with AMDT’s. This could result in annual energy savings of approximately 27 terawatt-hours (TWh) of core losses in the U.S.A. alone. These savings enable utilities to cost-effectively accommodate long-term growth in demand for power.

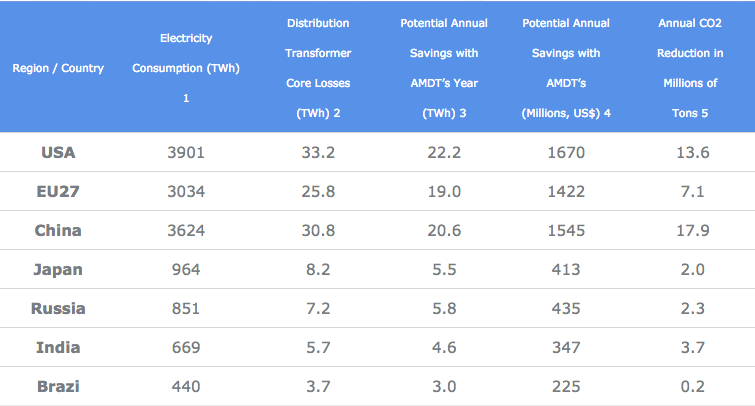

ENERGY SAVINGS BY COUNTRY

Projected Energy Savings Usings Metglas® AMDTs

In the year 2010, it was estimated that total energy savings for the regions listed would amount to 81(TWh) of core loss reduction per year or the equivalent of US $6.1 billion dollars annually. The reduction in the production of CO2, a major contributor to global warming, would be 47 million tons yearly.

| Region / Country | Electricity Consumption (TWh) 1 | Distribution Transformer Core Losses (TWh) 2 |

Potential Annual Savings with AMDT’s Year (TWh) 3 |

Potential Annual Savings with AMDT’s (Millions, US$) 4 |

Annual CO2 Reduction in Millions of Tons 5 |

| USA | 3901 | 33.2 | 22.2 | 1670 | 13.6 |

| EU27 | 3034 | 25.8 | 19.0 | 1422 | 7.1 |

| China | 3624 | 30.8 | 20.6 | 1545 | 17.9 |

| Japan | 964 | 8.2 | 5.5 | 413 | 2.0 |

| Russia | 851 | 7.2 | 5.8 | 435 | 2.3 |

| India | 669 | 5.7 | 4.6 | 347 | 3.7 |

| Brazi | 440 | 3.7 | 3.0 | 225 | 0.2 |

- 1 Enerdata Global Energy Statistical Yearbook 2010 and Eurelectric 2010 (2009 numbers) for EU27.

- 2 SEEDT Report EIE-05-056 and Metglas estimates

- 3 Based on Metglas experience

- 4 $0.075/kwhr Energy costs

- 5 Based on percentage and efficiency of thermal generation

“… new transformer core designs are emerging that use amorphous metal instead of the traditional silicon steel. These amorphous core transformers … offer up to 70 percent lower core losses than conventional transformers.”

~ The Office of Energy Efficiency Natural Resources Canada

ENERGY SAVINGS BY COUNTRY

Projected Energy Savings Usings Metglas® AMDTs

In the year 2010, it was estimated that total energy savings for the regions listed would amount to 81(TWh) of core loss reduction per year or the equivalent of US $6.1 billion dollars annually. The reduction in the production of CO2, a major contributor to global warming, would be 47 million tons yearly.

“… new transformer core designs are emerging that use amorphous metal instead of the traditional silicon steel. These amorphous core transformers … offer up to 70 percent lower core losses than conventional transformers.”

~ The Office of Energy Efficiency Natural Resources Canada

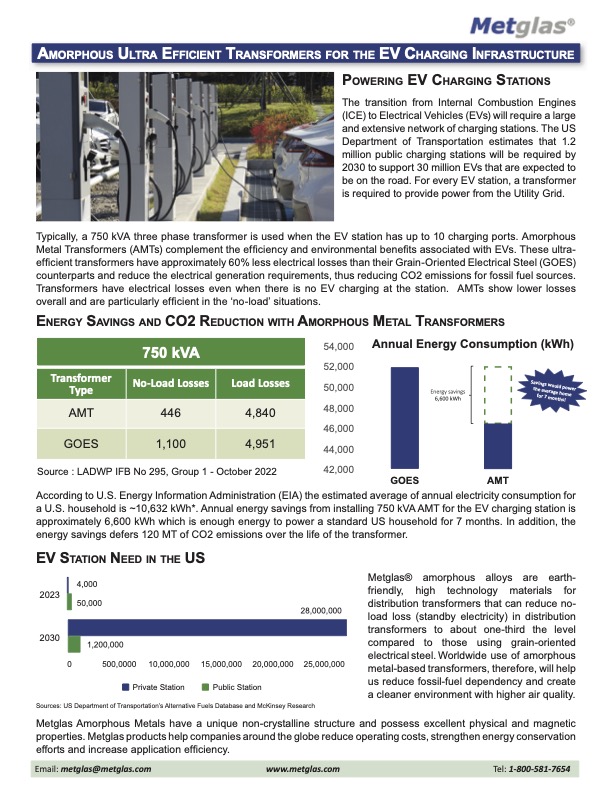

TRANSFORMER COMPARISON MODELS

From the generating station, electric power is transmitted at high voltages along power lines. Various stages of power and distribution transformers are then needed to “step down” the voltage to usable levels, e.g. 120-480 volts, for residential and industrial users. It is estimated that 2% of all electricity generated is lost due to distribution transformer inefficiency.

The Metglas® Transformer Comparison Model tool compares a standard silicon steel distribution transformer core and an amorphous distribution transformer core based on the performance characteristics. This tool does not design a transformer or create transformer performance parameters. The model will evaluate energy and economic savings under alternative load conditions.

The benefits of amorphous core distribution transformers are the greatest the lower the load and provide substantial savings for typical utilities with load factors of 35% or less.

* Please note, this tool does not design a transformer or create transformer performance parameters.

AMDTs FOR WIND FARMS

Natural Partner For Wind Turbines

- No Load Loss or Core Loss

– up to 70% lower - Increased Production Subsidy Exceeds Increased Transformer Cost – Additional No-Cost Sales

- Substantially Lower Transformer Costs and Lower Draw from Grid when not Generating

- Increased Contribution to Renewable Goals

- Lower Cost / MWh and Higher Profits

- Optimal Regardless of Energy Cost or Capacity Factor

AMDTs FOR WIND FARMS

Natural Partner For Wind Turbines

- No Load Loss or Core Loss

– up to 70% lower - Increased Production Subsidy Exceeds Increased Transformer Cost – Additional No-Cost Sales

- Substantially Lower Transformer Costs and Lower Draw from Grid when not Generating

- Increased Contribution to Renewable Goals

- Lower Cost / MWh and Higher Profits

- Optimal Regardless of Energy Cost or Capacity Factor

GOING GREEN WITH AMDTs

Metglas AMDTs can significantly reduce the impact on our global environment

Metglas® amorphous alloys are earth-friendly, high technology materials for distribution transformers that can reduce no-load loss (standby electricity) in distribution transformers to about one-third the level compared to those using grain-oriented electrical steel. Worldwide use of amorphous metal-based transformers, therefore, will help us reduce fossil-fuel dependency and create a cleaner environment with higher air quality.