PULSE POWER OVERVIEW

Saturable Reactors

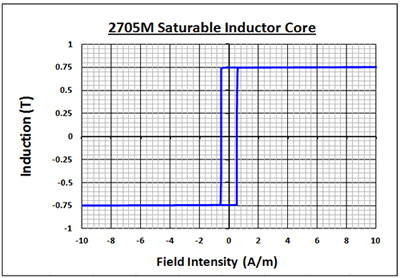

Saturable reactors utilize the large change between unsaturated and saturated permeabilities of their cores to delay current for a preset period of time. Similarly, once saturated in the forward direction, they act as a diode temporarily blocking current in the reverse direction.

Magnetic Switch Protection (MSP)

MSP devices made with Metglas® cores have dramatically enhanced the reliability and overall lifetime of pulse power systems. By using a saturable reactor in series with either a semiconductor or thyratron switch, the circuit designer can reduce losses in the switch and extend its life. The saturable reactor is designed to hold-off current until the switch becomes fully conductive (Figure 2).

This delay reduces the overlap between current and voltage in the switch, thereby reducing power absorber in the switch. MSP also offers other advantages. Higher di/dt’s to the load are safely achieved by waiting for full conductivity in semiconductor switches. The diode-like characteristic of a saturated reactor provides time for switch recovery.

Magnetic Pulse Compression (MPC)

Magnetic Pulse Compression (MPC) utilizes reactors (L1, L2, L3…) in conjunction with capacitors (C1,CL2,CL3…) to shape input pulses into narrow output pulses of much higher current (See figure 3 & 4). The MPC, therefore, allows the designer to use less expensive input switches with lower current ratings. MPC can also extend the lifetime of the input switch.

Advanced MPC devices – capable of generating power levels of multi-terawatts in tens of nanoseconds – have been realized utilizing Metglas® cores.

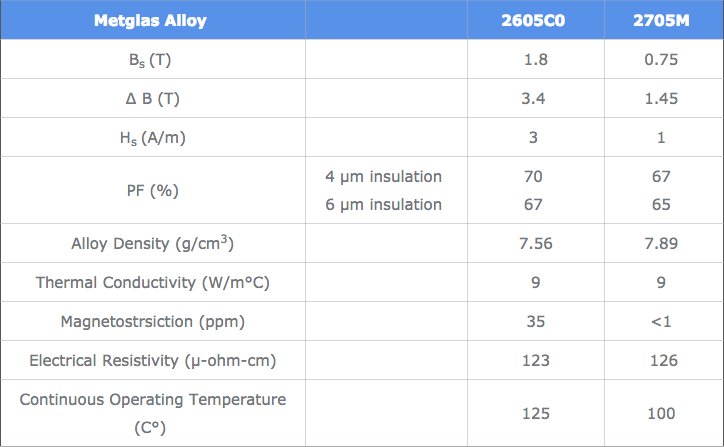

TYPICAL PULSE POWER CORE PROPERTIES

| Metglas Alloy | 2605C0 | 2705M | |

| Bs (T) | 1.8 | 0.75 | |

| ∆ B (T) | 3.4 | 1.45 | |

| Hs (A/m) | 3 | 1 | |

| PF (%) | 4 µm insulation 6 µm insulation |

70 67 |

67 65 |

| Alloy Density (g/cm3) | 7.56 | 7.89 | |

| Thermal Conductivity (W/m°C) | 9 | 9 | |

| Magnetostrsiction (ppm) | 35 | <1 | |

| Electrical Resistivity (µ-ohm-cm) | 123 | 136 | |

| Continuous Operating Temperature (C°) | 125 | 100 |

- Table

-

Metglas Alloy 2605C0 2705M Bs (T) 1.8 0.75 ∆ B (T) 3.4 1.45 Hs (A/m) 3 1 PF (%) 4 µm insulation

6 µm insulation70

6767

65Alloy Density (g/cm3) 7.56 7.89 Thermal Conductivity (W/m°C) 9 9 Magnetostrsiction (ppm) 35 <1 Electrical Resistivity (µ-ohm-cm) 123 136 Continuous Operating Temperature (C°) 125 100 - Graph

-

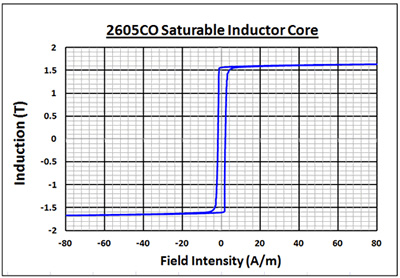

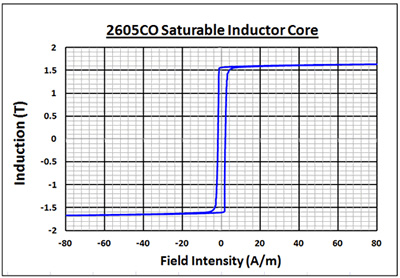

- BH Loop 1

-

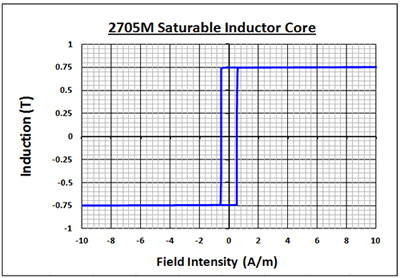

- BH Loop 2

-

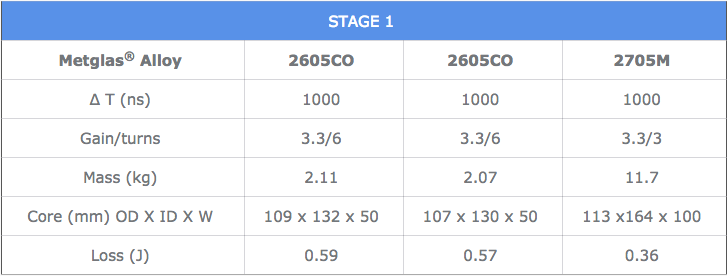

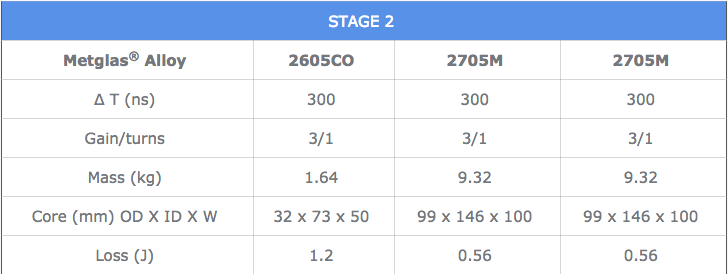

DESIGN EXAMPLES

As a design example we have chosen a 2-stage magnetic pulse compression network with a gain of 10 delivering 100 ns, 30 kV, 30 J pulsed to a laser load represented by a 67 nF peaking capacitor. Three examples are given (See table, below).

- Two stages 15µm Metglas® alloy 2605CO

- One stage each Metglas® alloys 2605CO and 2705M

- Two stages of 18 µm Metglas® alloy 2705M

Note that the system with the Alloy with the highest B has the least core mass, but the greatest loss. The largest increase in efficiency is achieved by using the lower loss alloy in the final stage.

| STAGE 1 | |||

| Metglas® Alloy | 2605CO | 2605CO | 2705M |

| Δ T (ns) | 1000 | 1000 | 1000 |

| Gain/turns | 3.3/6 | 3.3/6 | 3.3/3 |

| Mass (kg) | 2.11 | 2.07 | 11.7 |

| Core (mm) OD X ID X W | 109 x 132 x 50 | 107 x 130 x 50 | 113 x164 x 100 |

| Loss (J) | 0.59 | 0.57 | 0.36 |

| STAGE 2 | |||

| Metglas® Alloy | 2605CO | 2705M | 2705M |

| Δ T (ns) | 300 | 300 | 300 |

| Gain/turns | 3/1 | 3/1 | 3/1 |

| Mass (kg) | 1.64 | 9.32 | 9.32 |

| Core (mm) OD X ID X W | 32 x 73 x 50 | 99 x 146 x 100 | 99 x 146 x 100 |

| Loss (J) | 1.2 | 0.56 | 0.56 |

| TOTAL | |||

| Mass (Kg) | 3.75 | 11.4 | 21.08 |

| Loss (J) | 1.79 | 1.14 | 0.92 |

| Efficiency (%) | 94.4 | 96.3 | 97.0 |

- Stage 1

-

STAGE 1 Metglas® Alloy 2605CO 2605CO 2705M Δ T (ns) 1000 1000 1000 Gain/turns 3.3/6 3.3/6 3.3/3 Mass (kg) 2.11 2.07 11.7 Core (mm) OD X ID X W 109 x 132 x 50 107 x 130 x 50 113 x164 x 100 Loss (J) 0.59 0.57 0.36 - Stage 2

-

STAGE 2 Metglas® Alloy 2605CO 2705M 2705M Δ T (ns) 300 300 300 Gain/turns 3/1 3/1 3/1 Mass (kg) 1.64 9.32 9.32 Core (mm) OD X ID X W 32 x 73 x 50 99 x 146 x 100 99 x 146 x 100 Loss (J) 1.2 0.56 0.56 - Total

-

TOTAL Mass (Kg) 3.75 11.4 21.08 Loss (J) 1.79 1.14 0.92 Efficiency (%) 94.4 96.3 97.0

DESIGN EXAMPLES

As a design example we have chosen a 2-stage magnetic pulse compression network with a gain of 10 delivering 100 ns, 30 kV, 30 J pulsed to a laser load represented by a 67 nF peaking capacitor. Three examples are given (See table, below).

- Two stages 15µm Metglas® alloy 2605CO

- One stage each Metglas® alloys 2605CO and 2705M

- Two stages of 18 µm Metglas® alloy 2705M

Note that the system with the Alloy with the highest B has the least core mass, but the greatest loss. The largest increase in efficiency is achieved by using the lower loss alloy in the final stage.

ADDITIONAL PULSE CORE APPLICATIONS

Linear Induction Accelerators

Metglas® cores are used in linear induction accelerators to couple voltage pulse to the charge particle beam. These non-saturating cores are places in the accelerator cavities through which the beam passes. They function as 1:1 impedance matching transformers whose secondary voltage accelerates the particles in the beam. Metglas® cores offer high flux change, which minimizes the diameter of these large cores and, therefore, the size of the entire accelerator.

High Voltage Applications:

Metglas® cores are used as in some Magnetic Pulse Compression (MPC) systems. The use of high voltage transformers allows the designer to select input switches with reduced voltage ratings. Isolation transformers made with Metglas®cores and used with series connected secondaries can add up extremely high output voltage from isolated input voltage.

Additional Metglas® Pulse Power Core Applications:

There are a number of pulse power core applications where Metglas® cores are being used or offer future promise.

Laser Power Supplies

- Discharge Pumped Laser such as:

- Excimer Laser

- Metal Vapor Lasers

- CO2

- Used in the following applications:

- Medical Lasers

- Isotope Separation

- Photolithography Product Marking

- Industrial Welding

- Research

Induction Accelerators

- Drivers for Free Electron Laser

- E-BEAM source for industrial processing

- Radiation sources for waste sterilization

- High Power microwave sources (relativistic Klystrons)

- Heavy Ion accelerators for inertial confinement fusion research

ADDITIONAL PULSE CORE APPLICATIONS

Linear Induction Accelerators

Metglas® cores are used in linear induction accelerators to couple voltage pulse to the charge particle beam. These non-saturating cores are places in the accelerator cavities through which the beam passes. They function as 1:1 impedance matching transformers whose secondary voltage accelerates the particles in the beam. Metglas® cores offer high flux change, which minimizes the diameter of these large cores and, therefore, the size of the entire accelerator.

High Voltage Applications:

Metglas® cores are used as in some Magnetic Pulse Compression (MPC) systems. The use of high voltage transformers allows the designer to select input switches with reduced voltage ratings. Isolation transformers made with Metglas®cores and used with series connected secondaries can add up extremely high output voltage from isolated input voltage.

Additional Metglas® Pulse Power Core Applications:

There are a number of pulse power core applications where Metglas® cores are being used or offer future promise.

Laser Power Supplies

- Discharge Pumped Laser such as:

- Excimer Laser

- Metal Vapor Lasers

- CO2

- Used in the following applications:

- Medical Lasers

- Isotope Separation

- Photolithography Product Marking

- Industrial Welding

- Research

Induction Accelerators

- Drivers for Free Electron Laser

- E-BEAM source for industrial processing

- Radiation sources for waste sterilization

- High Power microwave sources (relativistic Klystrons)

- Heavy Ion accelerators for inertial confinement fusion research

TECHNICAL SUPPORT

For your pulse power applications Metglas®, Inc. will assist in materials selection and optimization of core designs. Contact Metglas, Inc. for further Information and a list of Technical Papers written by our technical staff.

This product may require licensing for export outside the United States:

Please visit the U.S. Dept of Commerce website to understand the necessary requirements.

Metglas®, Inc. requests that the applications and approval accompany any request for samples, quotations, or purchase orders.