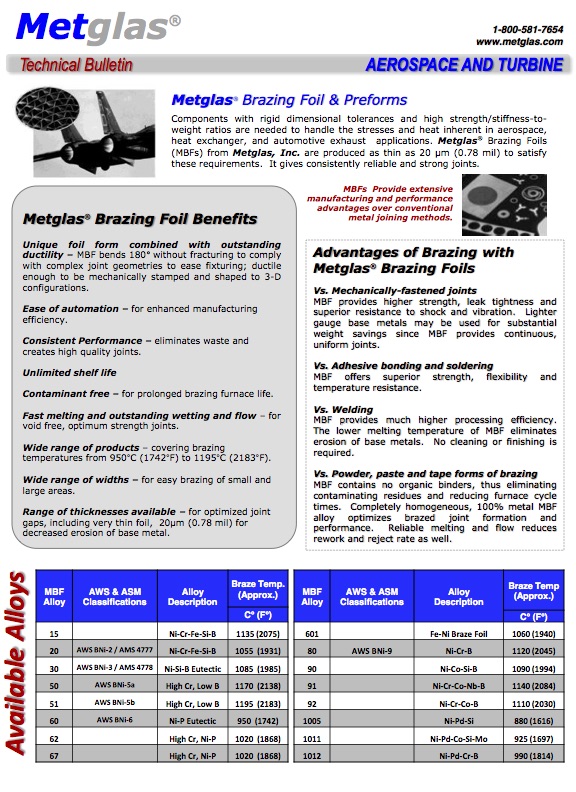

METGLAS HIGH PERFORMANCE BRAZING FILLER METALS

Metglas® Brazing Foils (MBF’s) and preforms provide extensive manufacturing and performance advantages over conventional metal joining materials. This unique form of amorphous nickel-based brazing filler metal can substitute for previously used copper foil or nickel powder to braze stainless steel base metal. This amorphous nickel foil provides high strength and outstanding corrosion resistance of brazed joints.

*Metglas Brazing Foils can be slit to specific widths and/or stamped into precise shapes for any application.

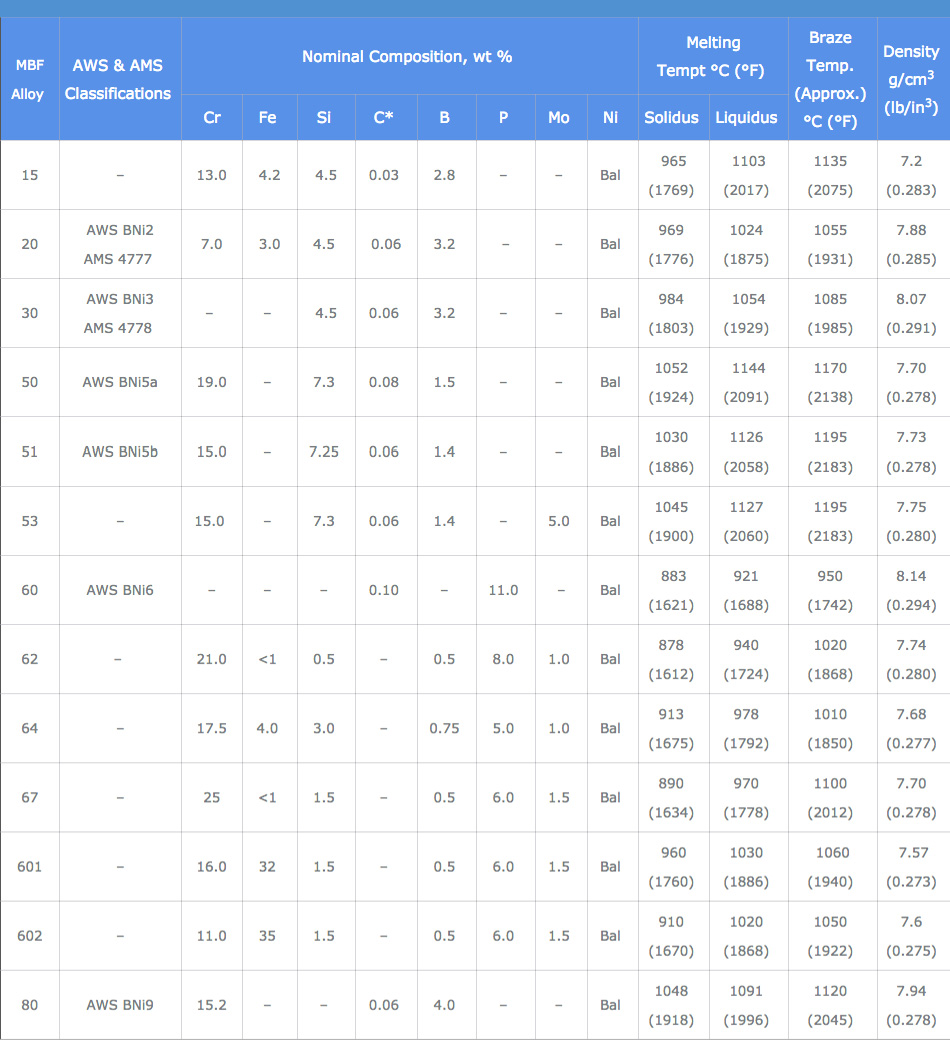

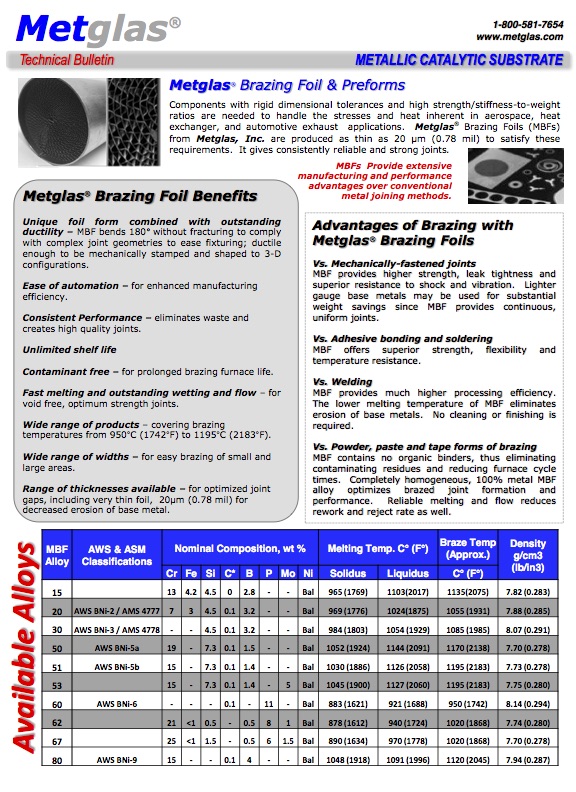

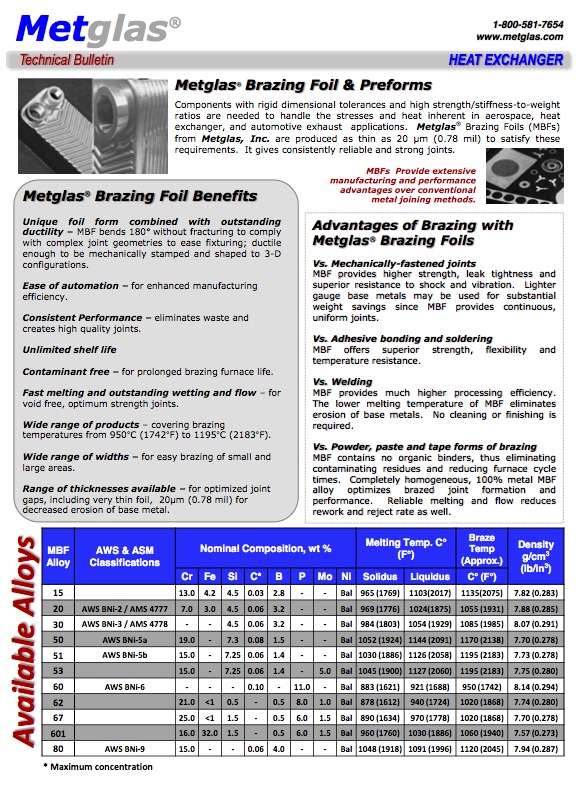

BRAZING ALLOYS

| Quote | AWS & AMS Classifications | Nominal Composition, wt % | Melting Tempt °C (°F) | Braze Temp. (Approx.) °C (°F) |

Density g/cm3 (lb/in3) |

||||||||

| Cr | Fe | Si | C* | B | P | Mo | Ni | Solidus | Liquidus | ||||

| MBF15 | – | 13.0 | 4.2 | 4.5 | 0.03 | 2.8 | – | – | Bal | 965 (1769) |

1103 (2017) |

1135 (2075) |

7.2 (0.283) |

| MBF20 | AWS BNi2 AMS 4777 |

7.0 | 3.0 | 4.5 | 0.06 | 3.2 | – | – | Bal | 969 (1776) |

1024 (1875) |

1055 (1931) |

7.88 (0.285) |

| MBF30 | AWS BNi3 AMS 4778 |

– | – | 4.5 | 0.06 | 3.2 | – | – | Bal | 984 (1803) |

1054 (1929) |

1085 (1985) |

8.07 (0.291) |

| MBF50 | AWS BNi5a | 19.0 | – | 7.3 | 0.08 | 1.5 | – | – | Bal | 1052 (1924) |

1144 (2091) |

1170 (2138) |

7.70 (0.278) |

| MBF51 | AWS BNi5b | 15.0 | – | 7.25 | 0.06 | 1.4 | – | – | Bal | 1030 (1886) |

1126 (2058) |

1195 (2183) |

7.73 (0.278) |

| MBF53 | – | 15.0 | – | 7.3 | 0.06 | 1.4 | – | 5.0 | Bal | 1045 (1900) |

1127 (2060) |

1195 (2183) |

7.75 (0.280) |

| MBF60 | AWS BNi6 | – | – | – | 0.10 | – | 11.0 | – | Bal | 883 (1621) |

921 (1688) |

950 (1742) |

8.14 (0.294) |

| MBF62 | – | 21.0 | <1 | 0.5 | – | 0.5 | 8.0 | 1.0 | Bal | 878 (1612) |

940 (1724) |

1020 (1868) |

7.74 (0.280) |

| MBF64 | – | 17.5 | 4.0 | 3.0 | – | 0.75 | 5.0 | 1.0 | Bal | 913 (1675) |

978 (1792) |

1010 (1850) |

7.68 (0.277) |

| MBF67 | – | 25 | <1 | 1.5 | – | 0.5 | 6.0 | 1.5 | Bal | 890 (1634) |

970 (1778) |

1100 (2012) |

7.70 (0.278) |

| MBF601 | – | 16.0 | 32 | 1.5 | – | 0.5 | 6.0 | 1.5 | Bal | 960 (1760) |

1030 (1886) |

1060 (1940) |

7.57 (0.273) |

| MBF602 | – | 11.0 | 35 | 1.5 | – | 0.5 | 6.0 | 1.5 | Bal | 910 (1670) |

1020 (1868) |

1050 (1922) |

7.6 (0.275) |

| MBF80 | AWS BNi9 | 15.2 | – | – | 0.06 | 4.0 | – | – | Bal | 1048 (1918) |

1091 (1996) |

1120 (2045) |

7.94 (0.278) |

*Maximum concentration

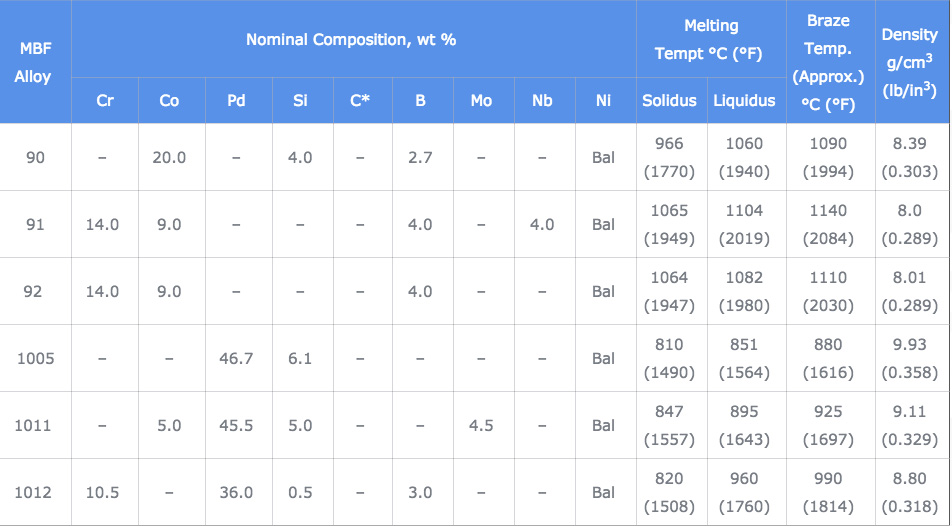

SPECIALTY ALLOYS

| Quote | Nominal Composition, wt % | Melting Tempt °C (°F) | Braze Temp. (Approx.) °C (°F) |

Density g/cm3 (lb/in3) |

|||||||||

| Cr | Co | Pd | Si | C* | B | Mo | Nb | Ni | Solidus | Liquidus | |||

| MBF90 | – | 20.0 | – | 4.0 | – | 2.7 | – | – | Bal | 966 (1770) |

1060 (1940) |

1090 (1994) |

8.39 (0.303) |

| MBF91 | 14.0 | 9.0 | – | – | – | 4.0 | – | 4.0 | Bal | 1065 (1949) |

1104 (2019) |

1140 (2084) |

8.0 (0.289) |

| MBF92 | 14.0 | 9.0 | – | – | – | 4.0 | – | – | Bal | 1064 (1947) |

1082 (1980) |

1110 (2030) |

8.01 (0.289) |

| MBF1005 | – | – | 46.7 | 6.1 | – | – | – | – | Bal | 810 (1490) |

851 (1564) |

880 (1616) |

9.93 (0.358) |

| MBF1011 | – | 5.0 | 45.5 | 5.0 | – | – | 4.5 | – | Bal | 847 (1557) |

895 (1643) |

925 (1697) |

9.11 (0.329) |

| MBF1012 | 10.5 | – | 36.0 | 0.5 | – | 3.0 | – | – | Bal | 820 (1508) |

960 (1760) |

990 (1814) |

8.80 (0.318) |

*Maximum concentration

APPLICATIONS FOR BRAZING FOIL

METGLAS HIGH PERFORMANCE BRAZING FILLER METALS

Metglas® Brazing Foils (MBF’s) and preforms provide extensive manufacturing and performance advantages over conventional metal joining materials. This unique form of amorphous nickel based brazing filler metal can substitute for previously used copper foil or nickel powder to braze stainless steel base metal. This amorphous nickel foil provides high strength and outstanding corrosion resistance of brazed joints.

*Metglas Brazing Foils can be slit to specific widths and/or stamped into precise shapes for any application.

*Maximum concentration

*Maximum concentration

APPLICATIONS FOR BRAZING FOIL

ADVANTAGES AND BENEFITS OF MBFs

Metglas Brazing Foils (MBF’s) provide extensive manufacturing and performance advantages over conventional brittle brazing filler metals. Some of these advantages include a wide variety of widths and thickness for any type of project, corrosive resistance for long lasting stability and ease of installation.

- Unique 100% metallic foil form possesing outstanding ductility

- MBF’s bend 180° without fracturing to comply with complex joint geometries to ease placement fixturing; ductile enough to be mechanically stamped and shaped to three-dimensional configurations.

- Wide range of brazing temperatures

- Covering melting temperatures from 950°C (1742°F) to 1195°C (2183°F).

- Contaminant-free

- For prolonged brazing furnace life.

- Fast melting and outstanding wetting and flow

- For void-free, optimum strength joints.

- Wide range of base metals successfully brazed

- Covering but not limited to all stainless steels, super alloys, hard cemented carbides and low carbon steels.

- Wide range of widths

- For easy brazing of small and large areas.

- Range of thicknesses available

- For optimized joint gaps, including very thin foil, 20µm (0.78 mil) for decreased erosion of base metal.

- Ease of assembling automation

- For enhanced manufacturing efficiency.

- Consistent performance

- A virtually reject-free brazing operation in one heating cycle.

- Precise metering and ability to be used as preforms

- Eliminates waste and creates high quality joints.

- Unlimited shelf life

- VS. Mechanically-fastened joints

- MBF’s provides higher strength, leak tightness, and superior resistance to shock and vibration. Lighter gauge base metals may be used for substantial weight savings since MBF’s provide continuous, uniform joints.

- VS. Welding

- MBF’s provides much higher processing efficiency. The lower melting temperature of MBF’s eliminates melting of base metals. No joint cleaning or finishing is required.

- VS. Adhesive bonding and soldering

- MBF’s offers superior strength, flexibility and temperature and oxidation resistance.

- VS. Powder, paste and tape forms of brazing

- MBF’s contains no organic binders, thus eliminating contaminating residues and reducing furnace cycle times. Completely homogeneous, 100% metal MBF’s alloy optimizes brazed joint formation and performance. Reliable melting and flow reduces rework and rejects too.

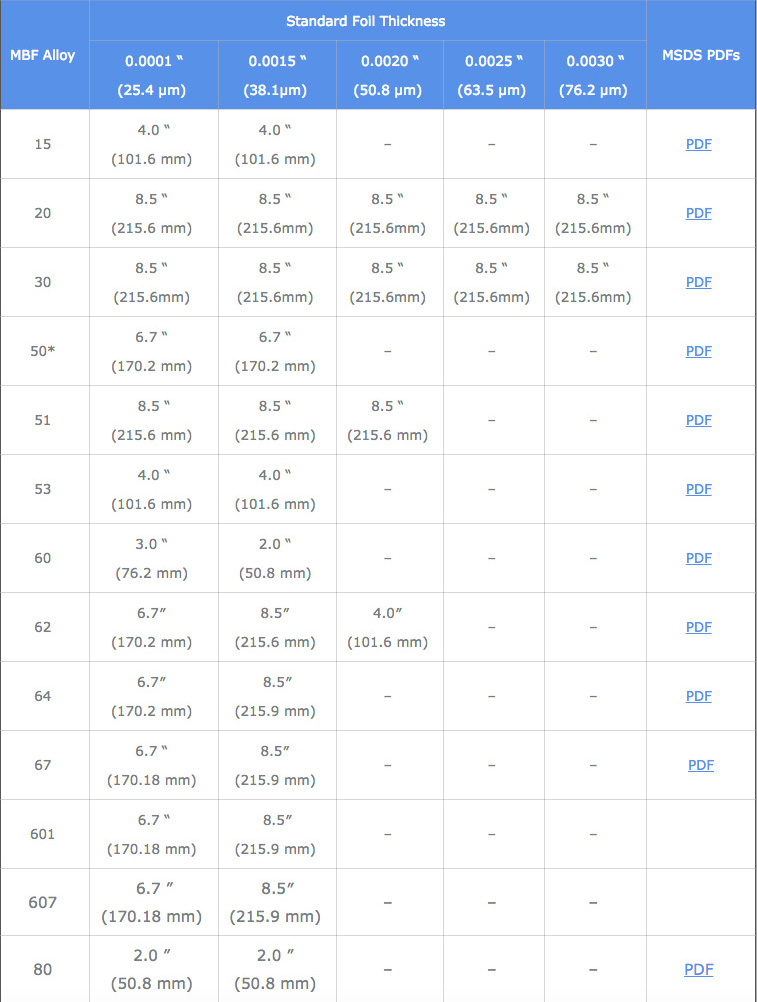

MAXIMUM WIDTHS BY THICKNESSES

Metglas® Brazing Foils can be produced in a number of widths and thickness configurations, use this chart to determine if we have a standard size that will fit your application. Widths and thicknesses not on this chart may be custom ordered.

| Quote | Standard Foil Thickness | SDS PDFs | ||||

| 0.0010 “ (25.4 µm) |

0.0015 “ (38.1µm) |

0.0020 “ (50.8 µm) |

0.0025 “ (63.5 µm) |

0.0030 “ (76.2 µm) |

||

| MBF15 | 4.0 “ (101.6 mm) |

4.0 “ (101.6 mm) |

– | – | – | |

| MBF20 | 8.5 “ (215.6 mm) |

8.5 “ (215.6mm) |

8.5 “ (215.6mm) |

8.5 “ (215.6mm) |

8.5 “ (215.6mm) |

|

| MBF30 | 8.5 “ (215.6mm) |

8.5 “ (215.6mm) |

8.5 “ (215.6mm) |

8.5 “ (215.6mm) |

8.5 “ (215.6mm) |

|

| MBF50* | 6.7 “ (170.2 mm) |

6.7 “ (170.18 mm) |

– | – | – | |

| MBF51 | 8.5 “ (215.6 mm) |

8.5 “ (215.6 mm) |

8.5 “ (215.6 mm) |

– | – | |

| MBF53 | 4.0 “ (101.6 mm) |

4.0 “ (101.6 mm) |

– | – | – | |

| MBF60 | 3.0 “ (76.2 mm) |

2.0 “ (50.8 mm) |

– | – | – | |

| MBF62 | 6.7″ (170.2 mm) |

8.5″ (215.6 mm) |

4.0″ (101.6 mm) |

– | – | |

| MBF64 | 6.7″ (170.2 mm) |

8.5″ (215.9 mm) |

– | – | – | |

| MBF67 | 6.7 “ (170.18 mm) |

8.5″ (215.9 mm) |

– | – | – | |

| MBF601 + 602 | 6.7 “ (170.18 mm) |

8.5″ (215.9 mm) |

– | – | – | |

| MBF80 | 2.0 “ (50.8 mm) |

2.0 “ (50.8 mm) |

– | – | – | |

* Available at thickness dow to 0.00078″ (20 µm).

Specialty Alloys available in 2.0 inch widths and various thickness

AVAILABLE WIDTHS & THICKNESSES REFERENCE

Metglas® Brazing Foils can be produced in a number of widths and thickness configurations, use this chart to determine if we have a standard size that will fit your application. Widths and thicknesses not on this chart may be custom ordered.

* Available at thickness dow to 0.00078″ (20 µm).

Specialty Alloys available in 2.0 inch widths and various thickness

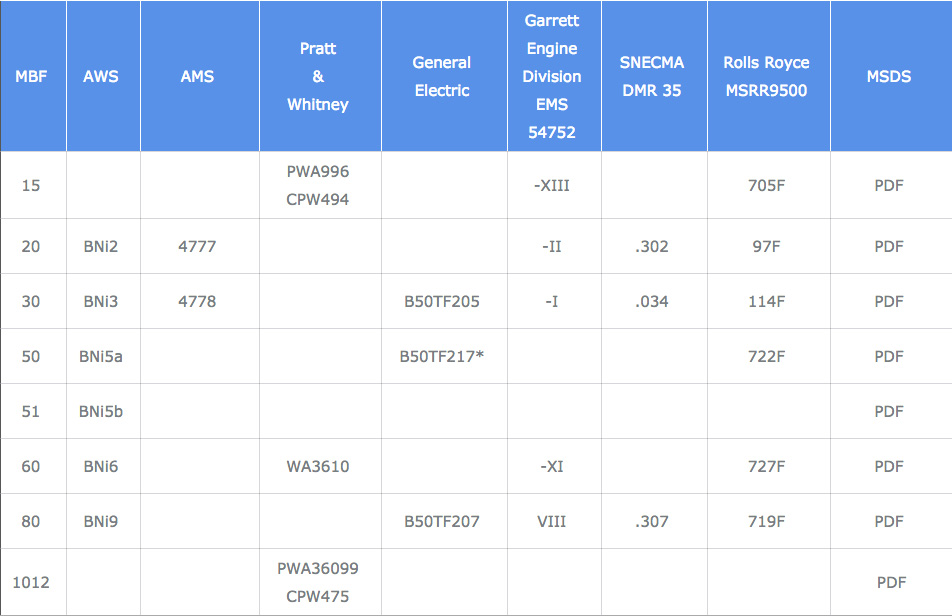

SPECIFICATIONS & CROSS REFERENCES

| Quote | AWS | AMS | Pratt & Whitney |

General Electric |

Garrett Engine Division EMS 54752 |

SNECMA DMR 35 |

Rolls Royce

MSRR9500 |

SDS

|

| MBF15 | – | – | PWA996 CPW494 |

– | -XIII | – |

705F

|

|

| MBF20 | BNi2 | 4777 | – | – | -II | .302 |

97F

|

|

| MBF30 | BNi3 | 4778 | – | B50TF205 | -I | .034 |

114F

|

|

| MBF50 | BNi5a | – | – | B50TF217* | – | – |

722F

|

|

| MBF51 | BNi5b | – | – | – | – | – | – | |

| MBF60 | BNi6 | – | WA3610 | – | -XI | – |

727F

|

|

| MBF80 | BNi9 | – | – | B50TF207 | VIII | .307 |

719F

|

|

| MBF1012 | – | – | PWA36099 CPW475 |

– | – | – | – |

* Alternative to GEB50TF81 powder and AMS 4782