- Cobalt containing alloys, ranging from 9-20 wt%

- Developed specifically for aerospace applications and the transient liquid phase (TLP) diffusion bonding process

- Highest solidus temperature out of any Metglas products for MBF91 and 92

- MBF91 contains niobium, which is a gamma prime phase former in super alloys

- Trials are currently being run on the XD-line

New MBF601 and MBF602 Alloy Composition

Available as a flexible 100% metallic foil having 18-50 um (0.7-2.0 mil) thickness and 50 mm (2″) width. Foil wider width may be supplied on a special request.

MBF-90 series have excellent high temperature and corrosive resistance. These alloys were specially designed to join super-alloys using TLP bonding.

| Alloy | Nominal Composition, wt % | Temp | Density g/cm | |||||||

| Ni | Cr | Co | Nb | B | Si | Other | Solidus | Liquid | ||

| MBF 90 | Bal | – | 20 | – | 2.7 | 4.0 | <0.5 | 966 (1770) |

1060 (1940) |

0.303 |

| MBF 91 | Bal | 14.0 | 9.0 | 4.0 | 4.0 | – | <0.5 | 1065 (1949) |

1104 (2019) |

TBD |

| MBF 92 | Bal | 14.0 | 9.0 | – | 4.0 | – | <0.5 | 1064 (1947) |

1082 (1980) |

TBD |

Recommendations:

Aircraft and power turbines, jet engine honeycombs, heat exchangers, fuel-cell elements and chemical apparatuses

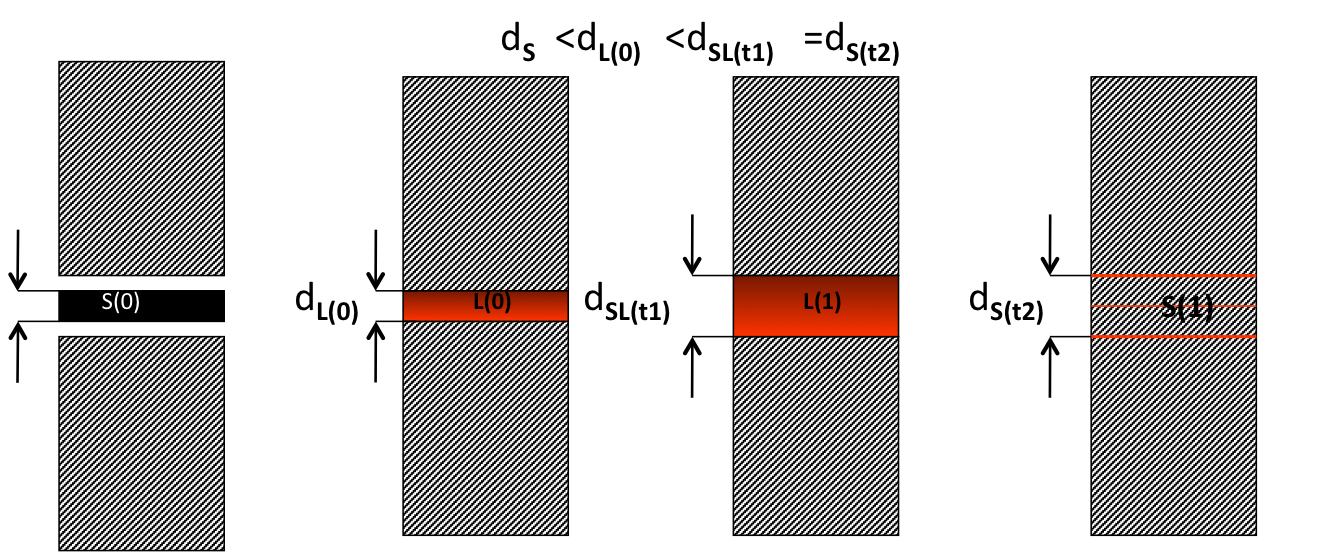

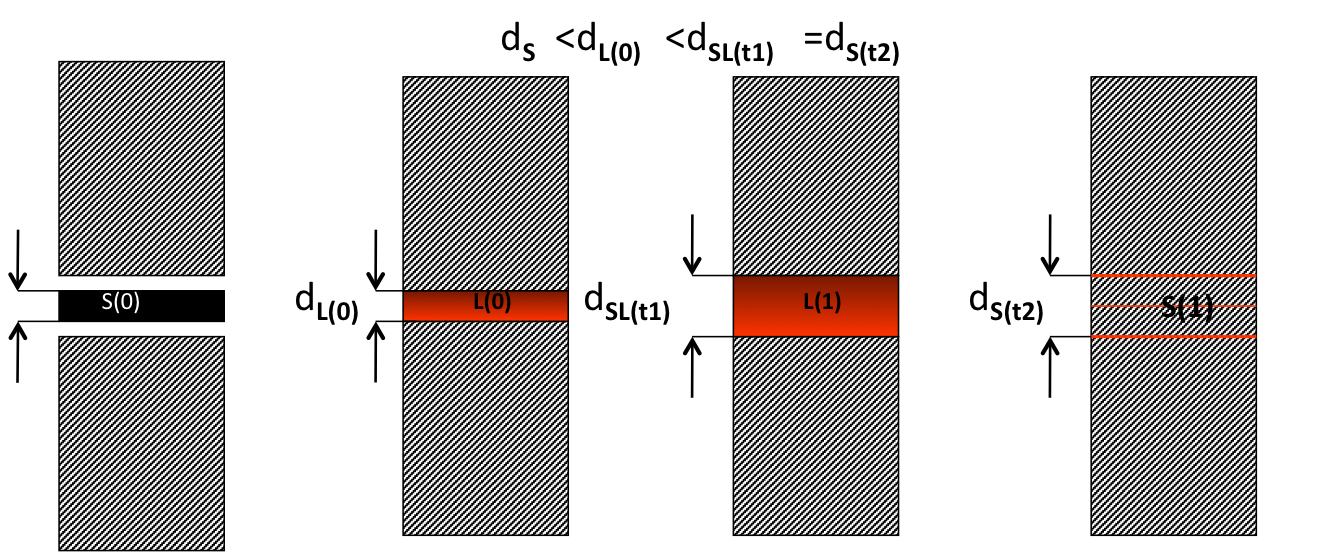

TLP Diffusion Brazing Process

- TLP diffusion bonding is a brazing process where the brazing filler metal acts as a catalyst to encourage diffusion between the base metals.

- Typically this is a two step process where the filler metal is melted in the brazing step and then diffusion occurs after a second stage annealing cycle

- These are very long cycle times ~2-8 hours but the resulting strength of the joint approaches the base material strength.

- Alloys

-

New MBF601 and MBF602 Alloy Composition

Available as a flexible 100% metallic foil having 18-50 um (0.7-2.0 mil) thickness and 50 mm (2″) width. Foil wider width may be supplied on a special request.

MBF-90 series have excellent high temperature and corrosive resistance. These alloys were specially designed to join super-alloys using TLP bonding.

Alloy Nominal Composition, wt % Temp Density g/cm Ni Cr Co Nb B Si Other Solidus Liquid MBF 90 Bal – 20 – 2.7 4.0 <0.5 966

(1770)1060

(1940)0.303 MBF 91 Bal 14.0 9.0 4.0 4.0 – <0.5 1065

(1949)1104

(2019)TBD MBF 92 Bal 14.0 9.0 – 4.0 – <0.5 1064

(1947)1082

(1980)TBD Recommendations:

Aircraft and power turbines, jet engine honeycombs, heat exchangers, fuel-cell elements and chemical apparatuses

- Diffusion

-

TLP Diffusion Brazing Process

- TLP diffusion bonding is a brazing process where the brazing filler metal acts as a catalyst to encourage diffusion between the base metals.

- Typically this is a two step process where the filler metal is melted in the brazing step and then diffusion occurs after a second stage annealing cycle

- These are very long cycle times ~2-8 hours but the resulting strength of the joint approaches the base material strength.