- High Chromium Alloy (25 wt%)

- Designed for use in automotive heat exchangers and brazed on a belt furnace

- Brazing temperature, 1080°C

New MBF62, MBF64 and MBF67 Alloy Composition

| Alloy | Nominal Composition, wt % | Temp | Density g/cm | |||||||

| Ni | Cr | Fe | Si | B | P | Mo | Solidus | Liquid | ||

| MBF62 | Bal | 21 | <1 | 0.5 | 0.5 | 8.0 | 1.0 | 878 (1612) |

990 (1814) |

7.74 |

| MBF64 | Bal | 17.5 | 4.0 | 3.0 | 0.8 | 5.0 | 1.0 | 913 (1675) |

978 (1792) |

7.68 |

| MBF67 | Bal | 25 | <1 | 1.5 | 0.5 | 6.0 | 1.5 | 890 (1634) |

970 (1778) |

7.70 |

Available Geometry

| Maximum Width by Thickness | |||

| Alloy | Standard | ||

| 0.0010″ (25.4 µm) |

0.0015″ (38.1 µm) |

0.0020″ (50.8 µm) |

|

| MBF62 | 6.7″ (170.18 mm) |

8.5″ (38.1 mm) |

6.7″ (50.8 mm) |

| MBF64 | 6.7″ (170.18 mm) |

8.5″ (38.1 mm) |

– |

| MBF67* | 6.7″ (170.18 mm) |

8.5″ (38.1 mm) |

– |

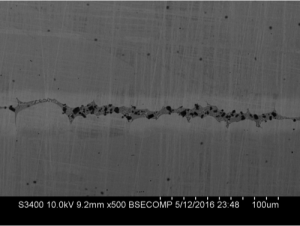

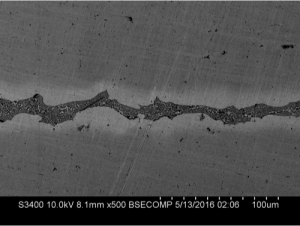

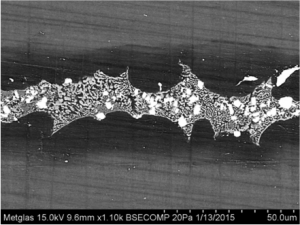

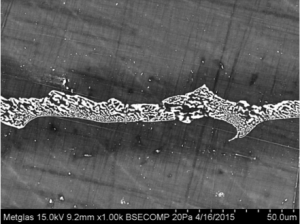

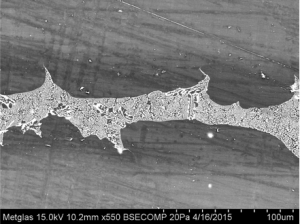

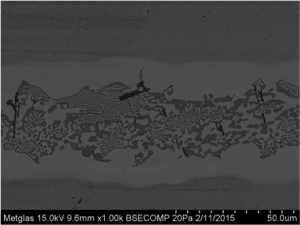

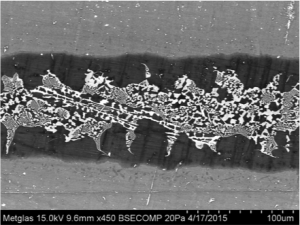

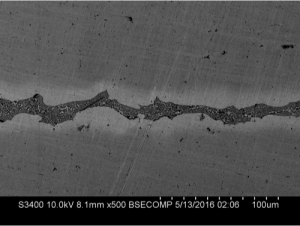

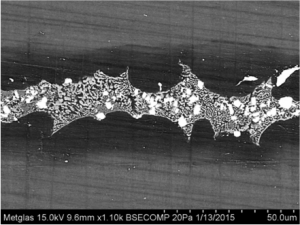

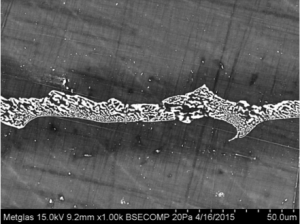

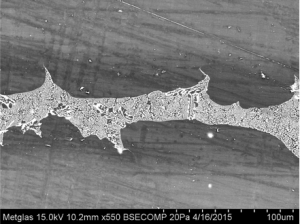

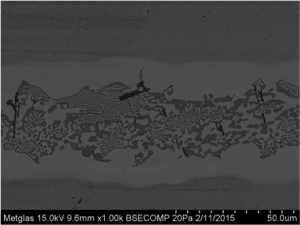

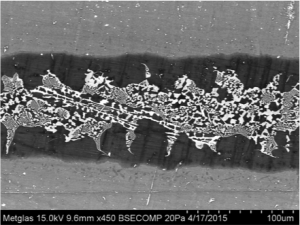

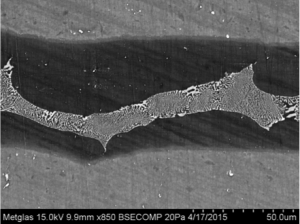

MBF67 Microstructure – Increased Time and Temperature

Longer braze times and temperature show less blocky Cr phases and more refined intermetallic phases along the centerline

|

1090 C – 15 minutes |

1095 C – 15 minutes |

1090 C – 60 minutes |

|

| SS316 |  |

|

|

| SS444 |  |

|

|

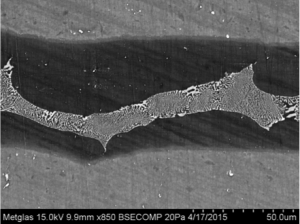

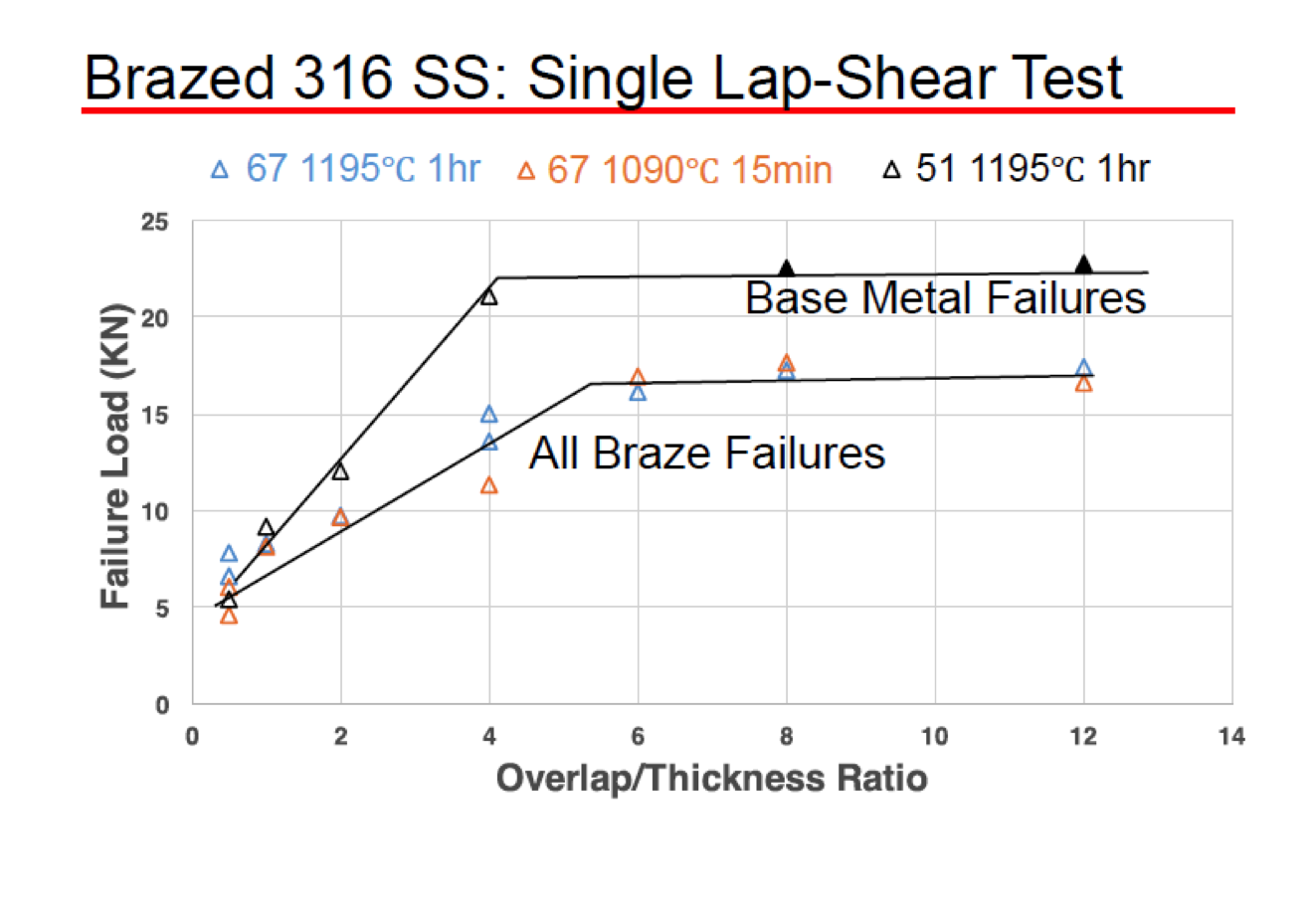

Brazed 316 SS: Single Lap-Shear Test

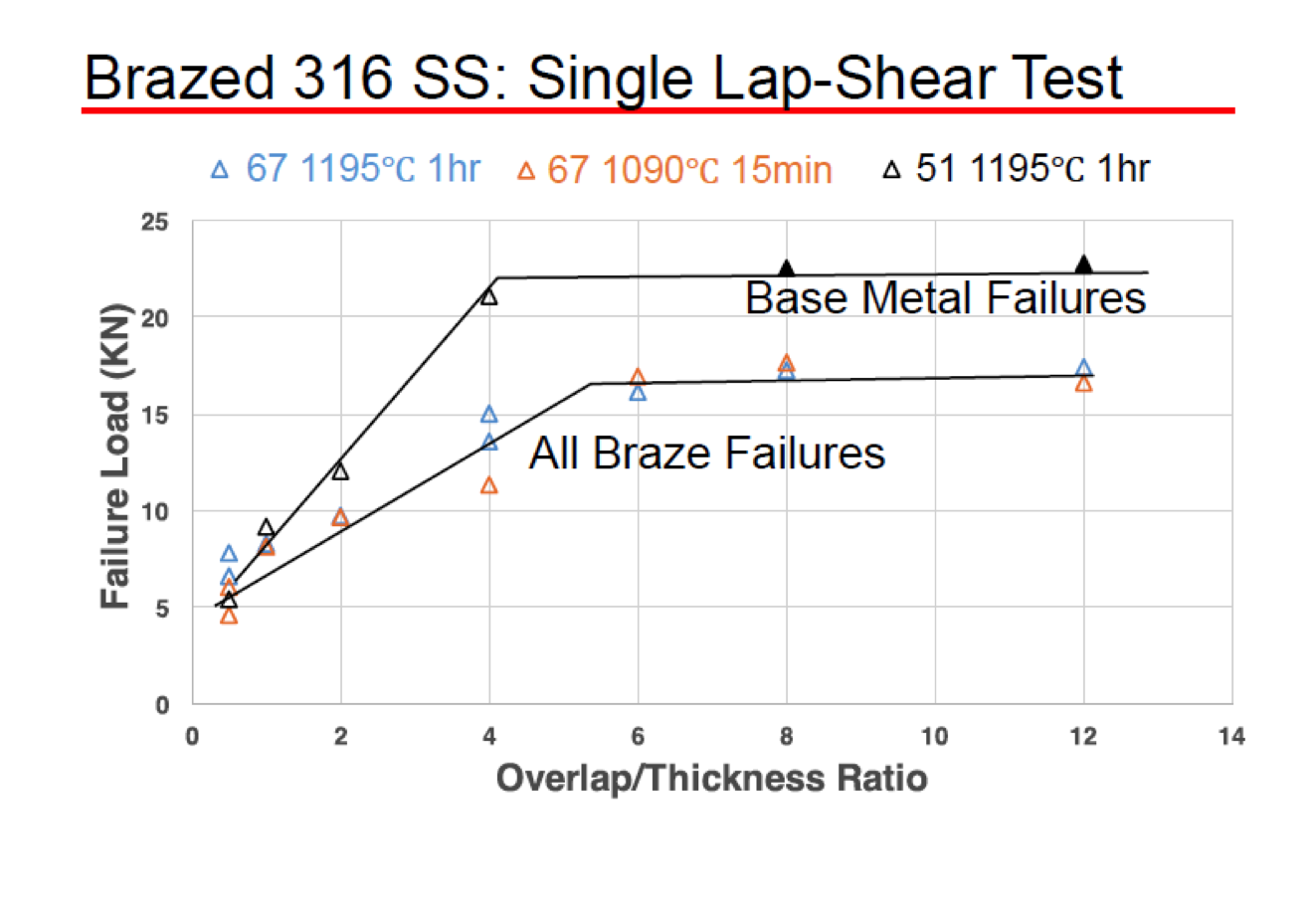

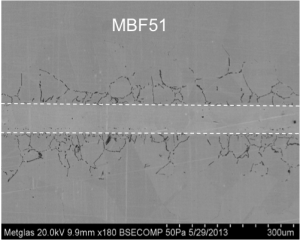

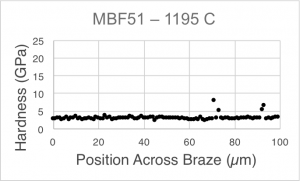

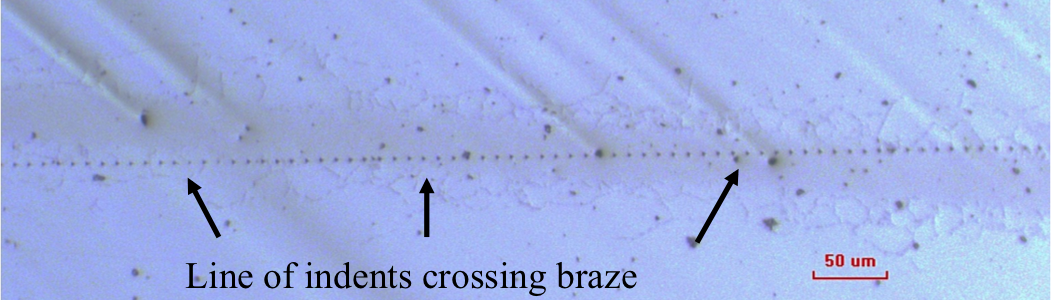

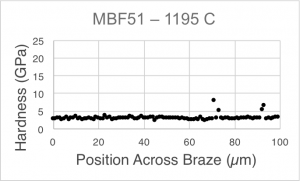

Nano-indentation of SS316 Joined with MBF51

Uniform and low hardness across the braze layer

|

|

|

|

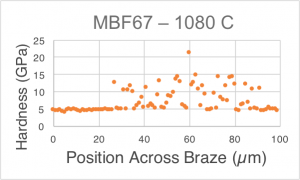

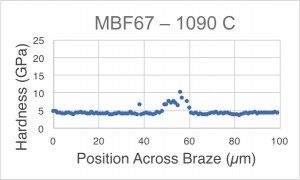

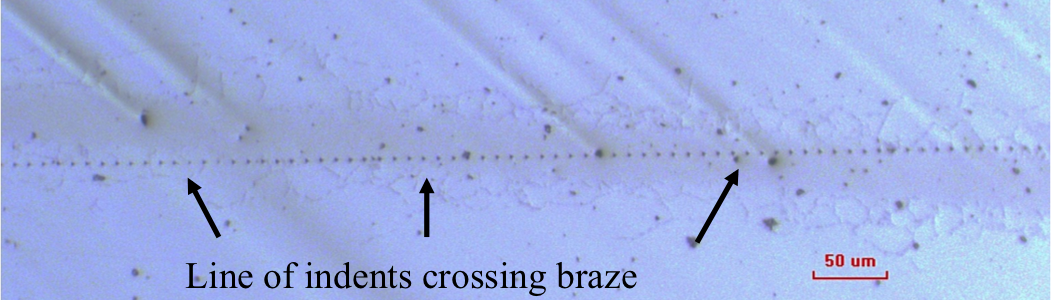

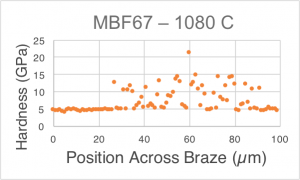

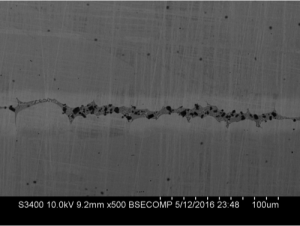

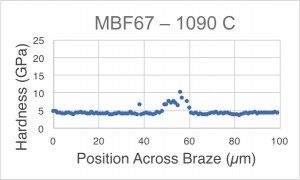

Nano-indentation of SS316 Joined with MBF67

Intermetallic phases within the braze layer have high hardness

|

|

|

|

- Alloys

-

New MBF62, MBF64 and MBF67 Alloy Composition

Alloy Nominal Composition, wt % Temp Density g/cm Ni Cr Fe Si B P Mo Solidus Liquid MBF62 Bal 21 <1 0.5 0.5 8.0 1.0 878

(1612)990

(1814)7.74 MBF64 Bal 17.5 4.0 3.0 0.8 5.0 1.0 913

(1675)978

(1792)7.68 MBF67 Bal 25 <1 1.5 0.5 6.0 1.5 890

(1634)970

(1778)7.70 - Geometry

-

Available Geometry

Maximum Width by Thickness Alloy Standard 0.0010″

(25.4 µm)0.0015″

(38.1 µm)0.0020″

(50.8 µm)

MBF62 6.7″

(170.18 mm)8.5″

(38.1 mm)6.7″

(50.8 mm)MBF64 6.7″

(170.18 mm)8.5″

(38.1 mm)– MBF67* 6.7″

(170.18 mm)8.5″

(38.1 mm)– - Structure

-

MBF67 Microstructure – Increased Time and Temperature

Longer braze times and temperature show less blocky Cr phases and more refined intermetallic phases along the centerline

1090 C – 15 minutes

1095 C – 15 minutes

1090 C – 60 minutes

SS316

SS444

- Lap-Shear

-

Brazed 316 SS: Single Lap-Shear Test

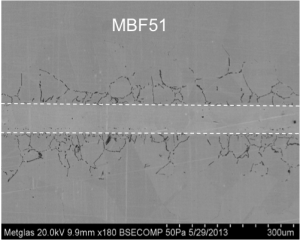

- MBF51

-

Nano-indentation of SS316 Joined with MBF51

Uniform and low hardness across the braze layer

- MBF67

-

Nano-indentation of SS316 Joined with MBF67

Intermetallic phases within the braze layer have high hardness