- High Iron content alloy (32 wt%)

- Designed for lower price than other Ni-based alloys while still maintaining good corrosion resistance

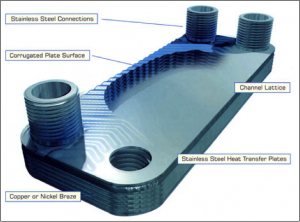

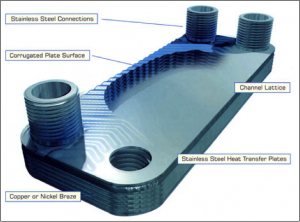

- Applications include oil-cooler and water heat applications

- Brazing temperature, 1060°C

New MBF601 and MBF602 Alloy Composition

| Alloy | Nominal Composition, wt % | Temp | Density g/cm | |||||||

| Ni | Cr | Fe | Si | B | P | Mo | Solidus | Liquid | ||

| MBF601 | Bal | 16 | 32 | 1.5 | 0.5 | 6.0 | 1.5 | 960 (1760) |

1030 (1886) |

7.57 |

| MBF602 | Bal | 11 | 35 | 1.5 | 0.5 | 6.0 | 1.5 | 910 (1670) |

1020 (1868) |

7.60 |

Available Geometry

| Maximum Width by Thickness | |||

| Alloy | Standard Thickness | ||

| 0.0010″ (25.4 µm) |

0.0015″ (38.1 µm) |

0.0020″ (50.8 µm) |

|

| MBF601* | 6.7″ (170.18 mm) |

8.5″ (38.1 mm) |

– |

| MBF602* | 6.7″ (170.18 mm) |

8.5″ (38.1 mm) |

– |

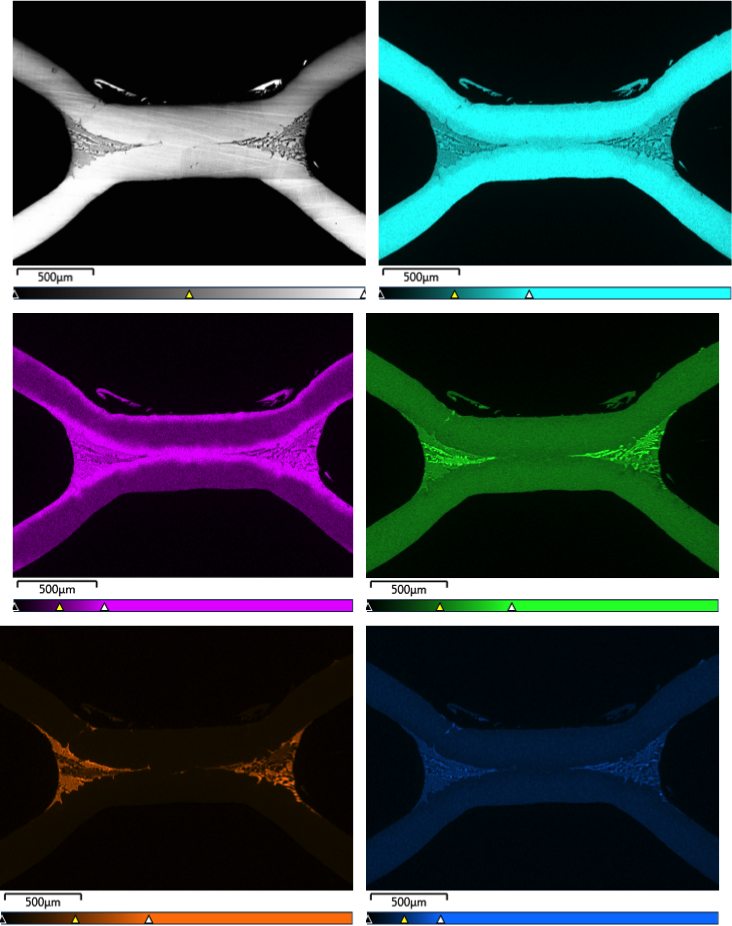

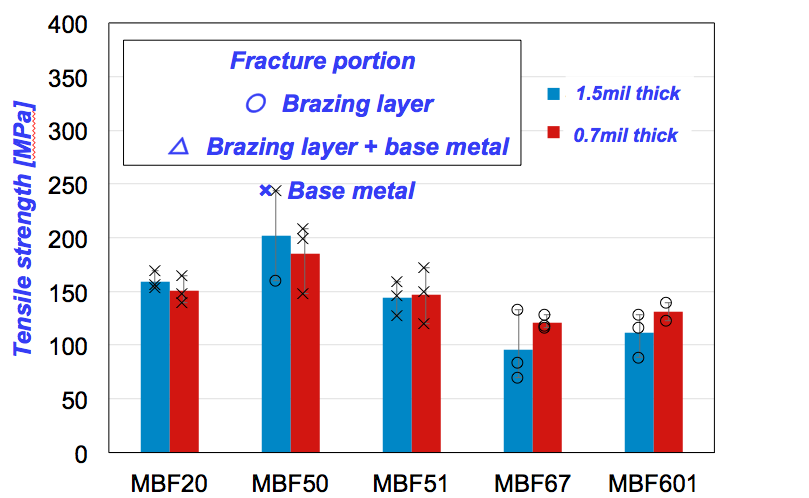

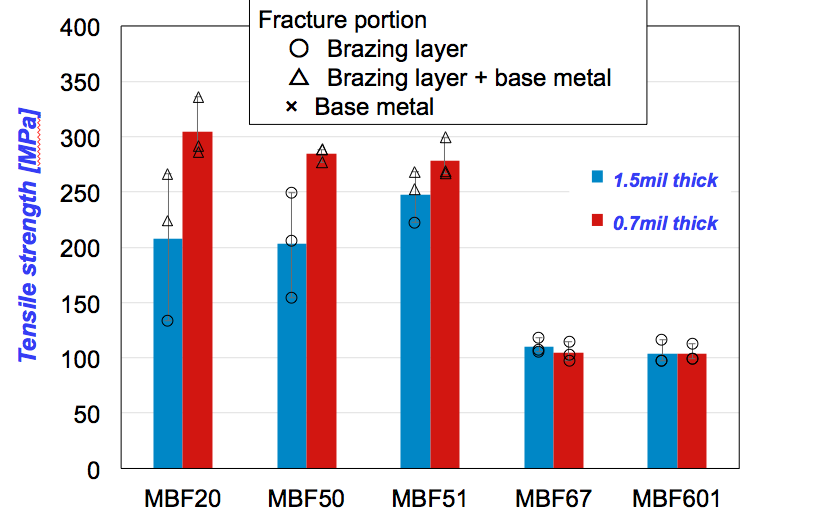

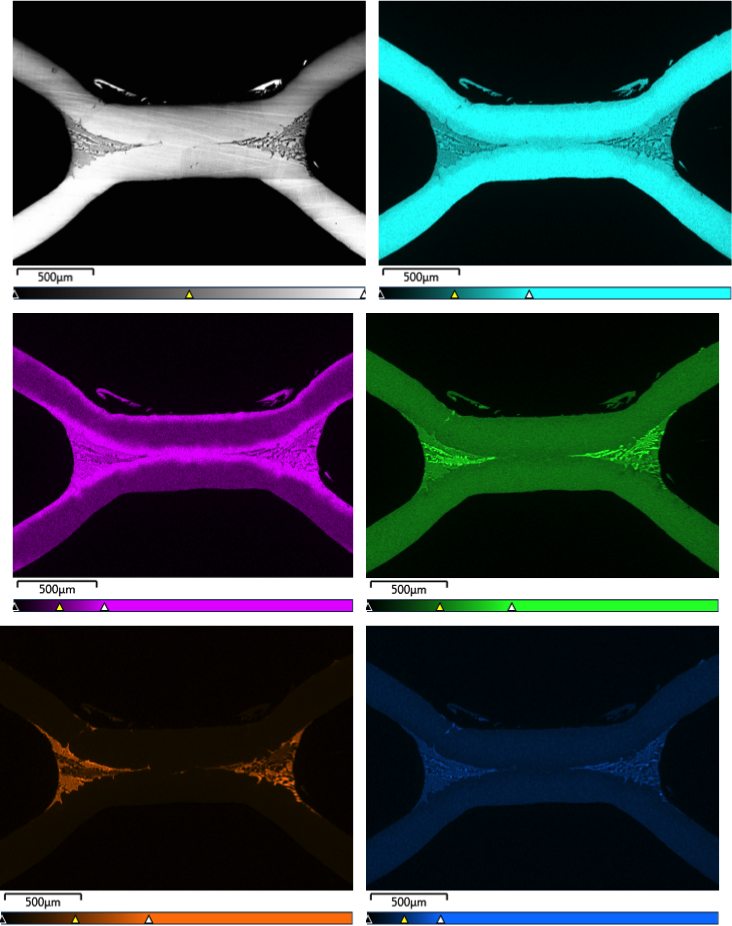

Elemental Analysis of MBF601 Braze Joint

–Failure analysis completed on brazed plate heat exchanger

–Example of braze joint that exhibits excellent burst pressure

–Contact points show very little intermetallics

–High Cr in braze joint for added corrosion resistance

–Very little phosphorus diffusion into parent material

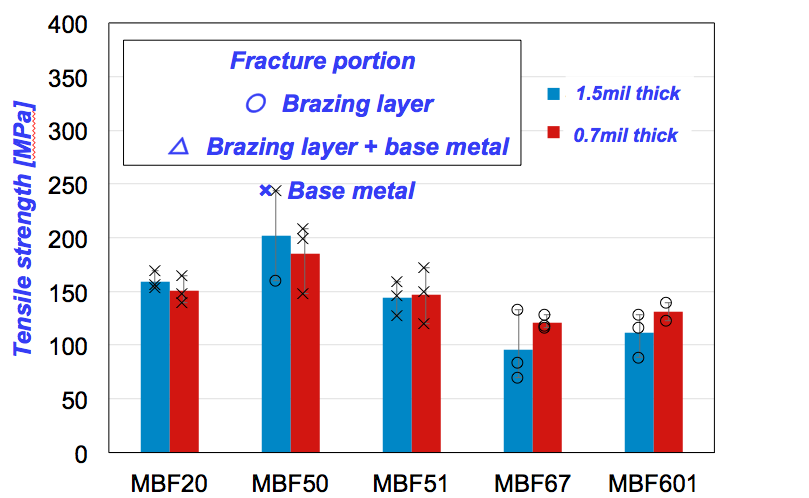

SUS444 1050/1150℃-5min in vacuum

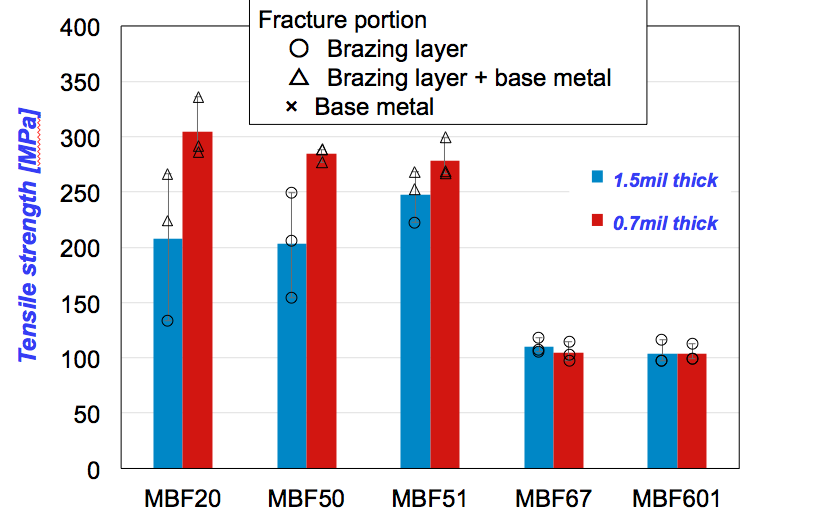

SUS316L 1050/1150℃-5min in vacuum

Applications for MBF67 and 601

Automotive

- Applications: EGR Coolers, Heat Collectors, Oil Coolers, Metallic Catalytic Converters

Industrial

- Applications: Water heater, refrigeration heat exchangers

|

|

- Alloys

-

New MBF601 and MBF602 Alloy Composition

Alloy Nominal Composition, wt % Temp Density g/cm Ni Cr Fe Si B P Mo Solidus Liquid MBF601 Bal 16 32 1.5 0.5 6.0 1.5 960

(1760)1030

(1886)7.57 MBF602 Bal 11 35 1.5 0.5 6.0 1.5 910

(1670)1020

(1868)7.60 - Geometry

-

Available Geometry

Maximum Width by Thickness Alloy Standard Thickness 0.0010″

(25.4 µm)0.0015″

(38.1 µm)0.0020″

(50.8 µm)

MBF601* 6.7″

(170.18 mm)8.5″

(38.1 mm)– MBF602* 6.7″

(170.18 mm)8.5″

(38.1 mm)– - Anaylsis

-

Elemental Analysis of MBF601 Braze Joint

–Failure analysis completed on brazed plate heat exchanger

–Example of braze joint that exhibits excellent burst pressure

–Contact points show very little intermetallics

–High Cr in braze joint for added corrosion resistance

–Very little phosphorus diffusion into parent material

- SUS444

-

SUS444 1050/1150℃-5min in vacuum

- SUS316L

-

SUS316L 1050/1150℃-5min in vacuum

- Applications

-

Applications for MBF67 and 601

Automotive

- Applications: EGR Coolers, Heat Collectors, Oil Coolers, Metallic Catalytic Converters

Industrial

- Applications: Water heater, refrigeration heat exchangers