- Nickel-Palladium alloys with 36-46 wt% palladium

- Re-introduced to the Metglas product line after an multiple customer inquiries

- Developed for turbine repair (aerospace industry) and polycrystalline diamond brazing onto cemented carbide substrates (down hole drilling applications)

- Commercial alloy

New MBF1005 and MBF1011 Alloy Composition

MBF 1005 and 1011 were specifically design to have a brazing temperature below 900 C to reduce thermal stresses from the brazing processes and prevent polycrystalline diamond from graphitization. The low silicon content and lack of boron help reduce intermetallic particles in the braze joint and increase joint strength.

All MBF 1000 series alloys can be used to join 300 series stainless steel and nickel based super-alloys. Braze joints with these materials exhibit very high corrosion resistance and low erosion of base metal. Available as flexible 100% metallic foil having 18-50 um (0.7-2.0 mil) thickness and 50 mm (2″) width. Foil with wider may be supplied on a special request.

Recommended Applications:

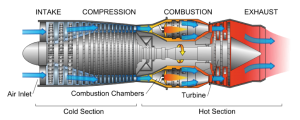

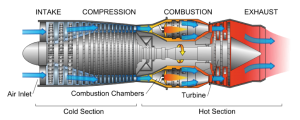

Aircraft and power turbines, diamond tipped tools and drill bits.

| Alloy | Nominal Composition, wt % | Temp | Density g/cm | |||||||

| Ni | Cr | Pd | Si | B | Co | Mo | Solidus | Liquid | ||

| MBF 1005 | Bal | – | 46.7 | 6.1 | – | – | – | 810 (1490) |

851 (1564) |

9.93 |

| MBF 1011 | Bal | – | 45.5 | 5.0 | – | 5.0 | 4.5 | 847 (1557) |

895 (1643) |

9.11 |

| MBF 1012 | Bal | 15.0 | 36.0 | 0.5 | 3.0 | – | – | 820 (1508) |

960 (1760) |

8.80 |

Recommendations:

Aircraft and power turbines, jet engine honeycombs, heat exchangers, fuel-cell elements and chemical apparatuses

Applications of MBF 1000 series

- Aerospace

- New Products: MBF90 series and 1000 Series\

- Applications: Turbine blade assembly and repair, felmetal sealling, honeycomb structures

- Down Hole Drilling

- MBF1000 Series

- Applications: Brazing polycrystalline diamond to cemented carbides

|

|

- Alloys

-

New MBF1005 and MBF1011 Alloy Composition

MBF 1005 and 1011 were specifically design to have a brazing temperature below 900 C to reduce thermal stresses from the brazing processes and prevent polycrystalline diamond from graphitization. The low silicon content and lack of boron help reduce intermetallic particles in the braze joint and increase joint strength.

All MBF 1000 series alloys can be used to join 300 series stainless steel and nickel based super-alloys. Braze joints with these materials exhibit very high corrosion resistance and low erosion of base metal. Available as flexible 100% metallic foil having 18-50 um (0.7-2.0 mil) thickness and 50 mm (2″) width. Foil with wider may be supplied on a special request.

Recommended Applications:

Aircraft and power turbines, diamond tipped tools and drill bits.

Alloy Nominal Composition, wt % Temp Density g/cm Ni Cr Pd Si B Co Mo Solidus Liquid MBF 1005 Bal – 46.7 6.1 – – – 810

(1490)851

(1564)9.93 MBF 1011 Bal – 45.5 5.0 – 5.0 4.5 847

(1557)895

(1643)9.11 MBF 1012 Bal 15.0 36.0 0.5 3.0 – – 820

(1508)960

(1760)8.80 Recommendations:

Aircraft and power turbines, jet engine honeycombs, heat exchangers, fuel-cell elements and chemical apparatuses

- Applications

-

Applications of MBF 1000 series

- Aerospace

- New Products: MBF90 series and 1000 Series\

- Applications: Turbine blade assembly and repair, felmetal sealling, honeycomb structures

- Down Hole Drilling

- MBF1000 Series

- Applications: Brazing polycrystalline diamond to cemented carbides

- Aerospace